I'd be very interested to see what equipment was used to check this

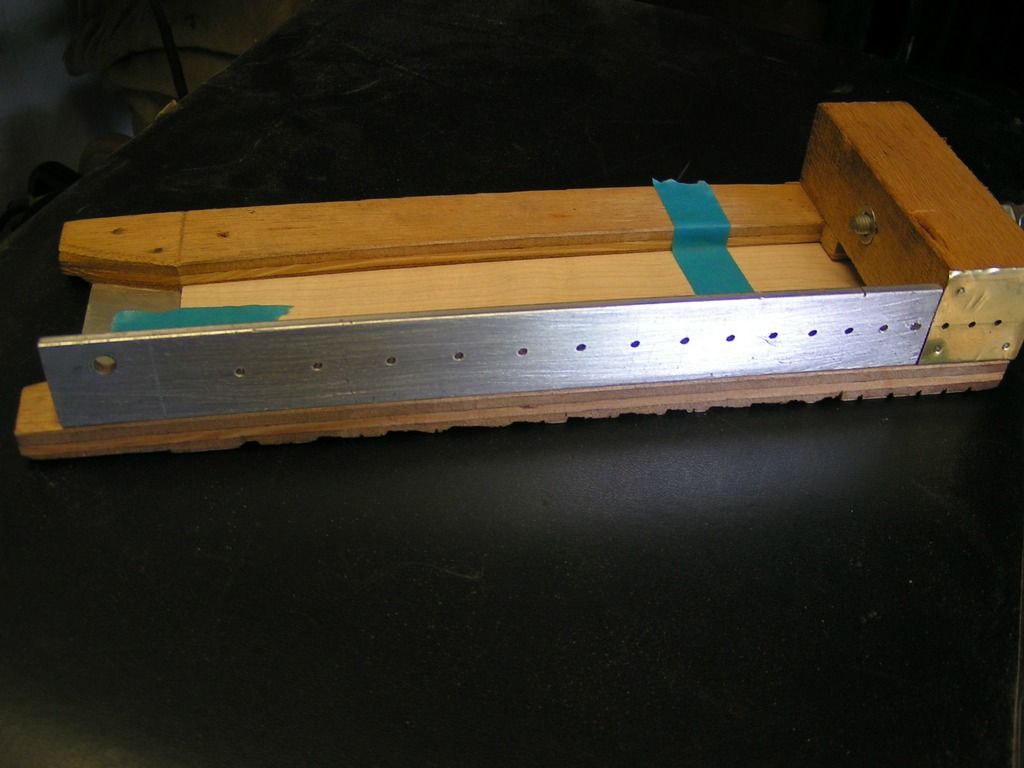

Just a cheap digital caliper and a little less cheap straight edge ruler. All them numbers come from the math, done in a spreadsheet with formulas so I don't have to do the math. So yeah, probably not as accurate as all that, but on the other hand, it could be even more accurate, I wouldn't know.