Timbuck

Well-known member

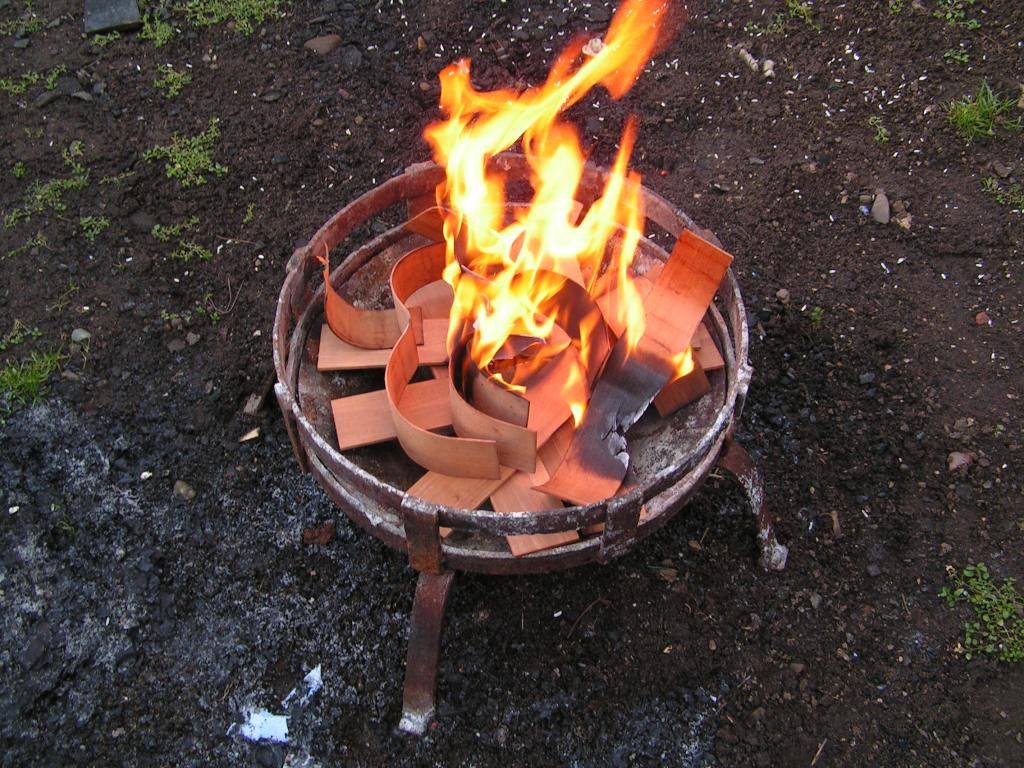

Yes ! The wrinkles are back..I tried the washing up liquid trick..also Chucks CA glue method ... I tried bending hotter, more slowly, and even praying to St Luthier all to no avail.....But I give in..When I've finished this cuppa tea I'm going back in the workshop and I'm going to destroy this batch of side wood before it makes me mentally ill :wallbash:....its a weird type of South Amercan mahogany with a very soft and wooly texture more like Balsa...its ok for tops and backs but sides NO !:wtf: