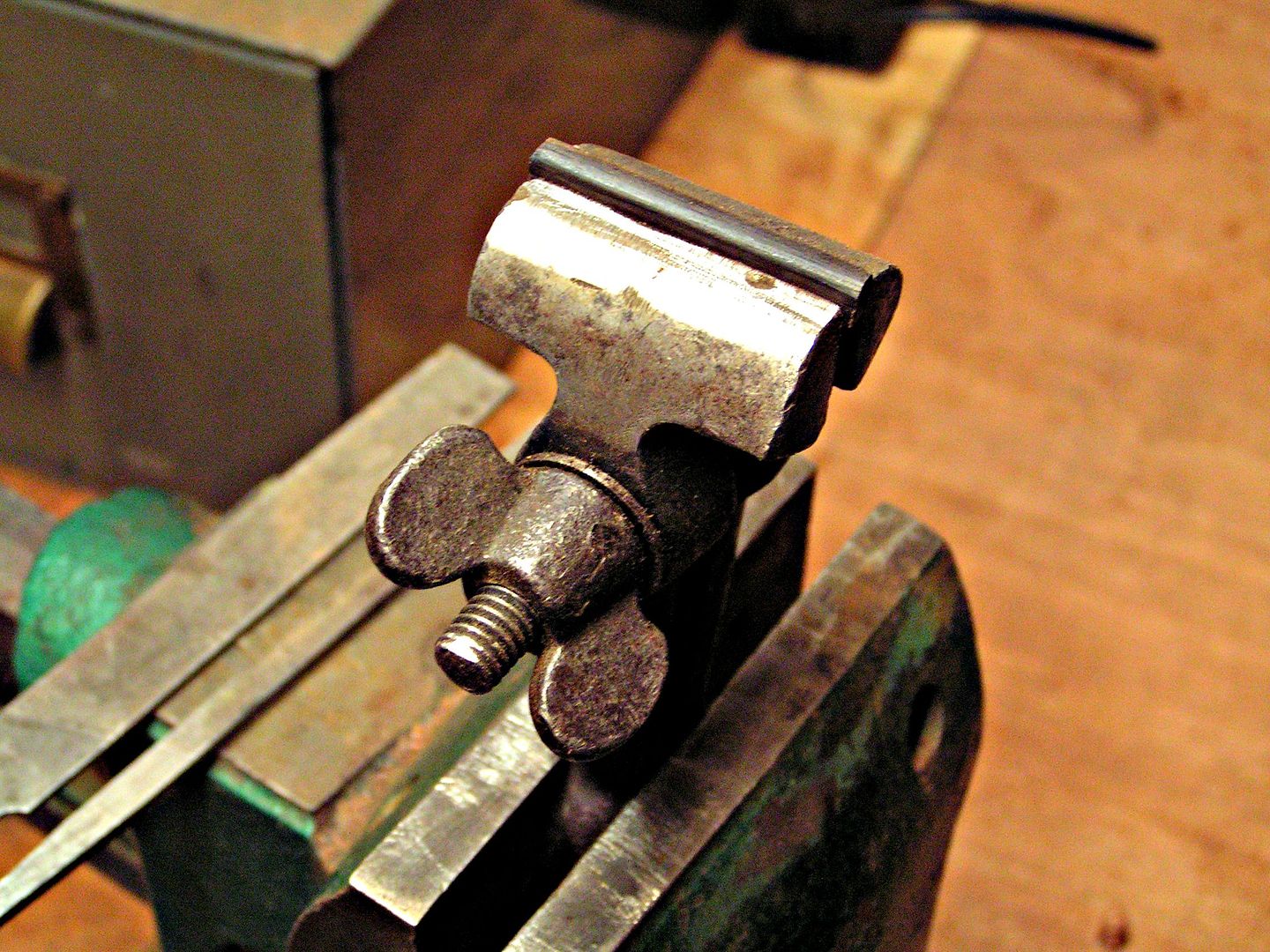

No, not that kind of vice. This kind of vise:

Sure, I could have bought the StewMac nut vise for $36.48 but this was easy to make and works very well. Holding the work piece well above the jaws of the parrot vise makes it much easier to file and sand, especially when shaping the top of a saddle. The plastic jaws won't mar anything that you'd make a nut or saddle out of. This came in handy while setting up a new build this afternoon so I thought it might be good time to show it off.

Sure, I could have bought the StewMac nut vise for $36.48 but this was easy to make and works very well. Holding the work piece well above the jaws of the parrot vise makes it much easier to file and sand, especially when shaping the top of a saddle. The plastic jaws won't mar anything that you'd make a nut or saddle out of. This came in handy while setting up a new build this afternoon so I thought it might be good time to show it off.

Last edited: