Timbuck

Well-known member

Many Years ago, long before I even thought of making a ukulele I designed and made some simple "Boring heads" for model engineers to use on their hobby milling machines. Slideshows of manufacture can be seen here Part 1 http://s219.photobucket.com/user/shiregreenbod/media/ea319039.pbw.html and here for Part 2 http://s219.photobucket.com/user/shiregreenbod/media/1f8d5156.pbw.html

And here's Part 3 http://s219.photobucket.com/user/shiregreenbod/media/4620d098.pbw.html

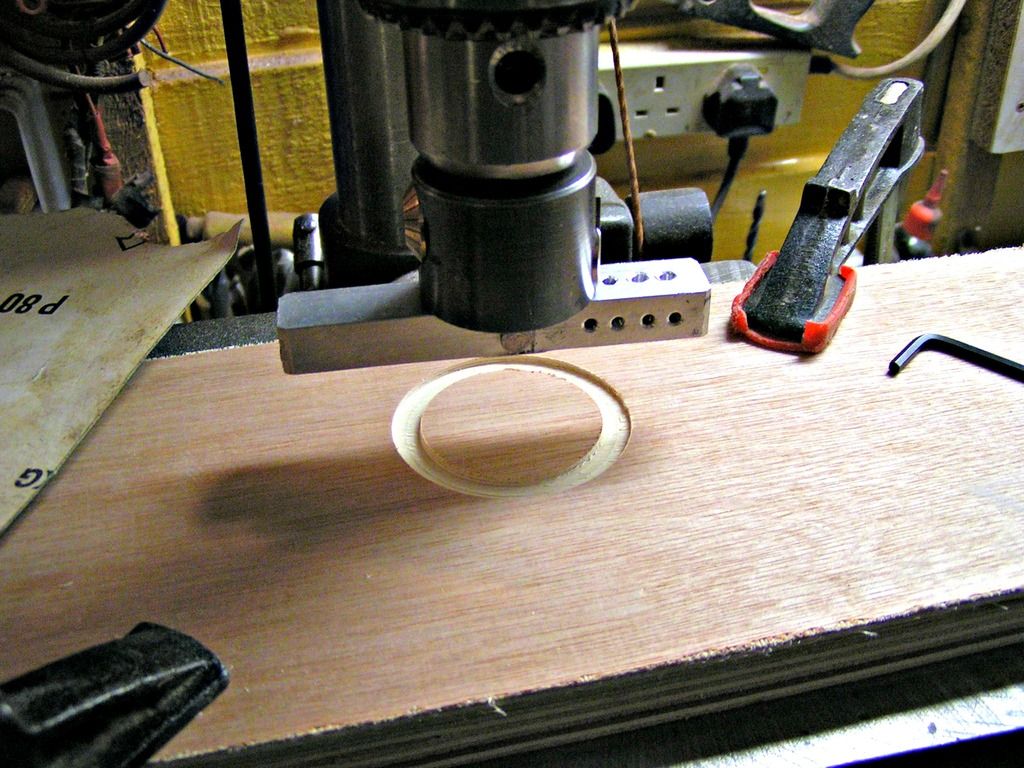

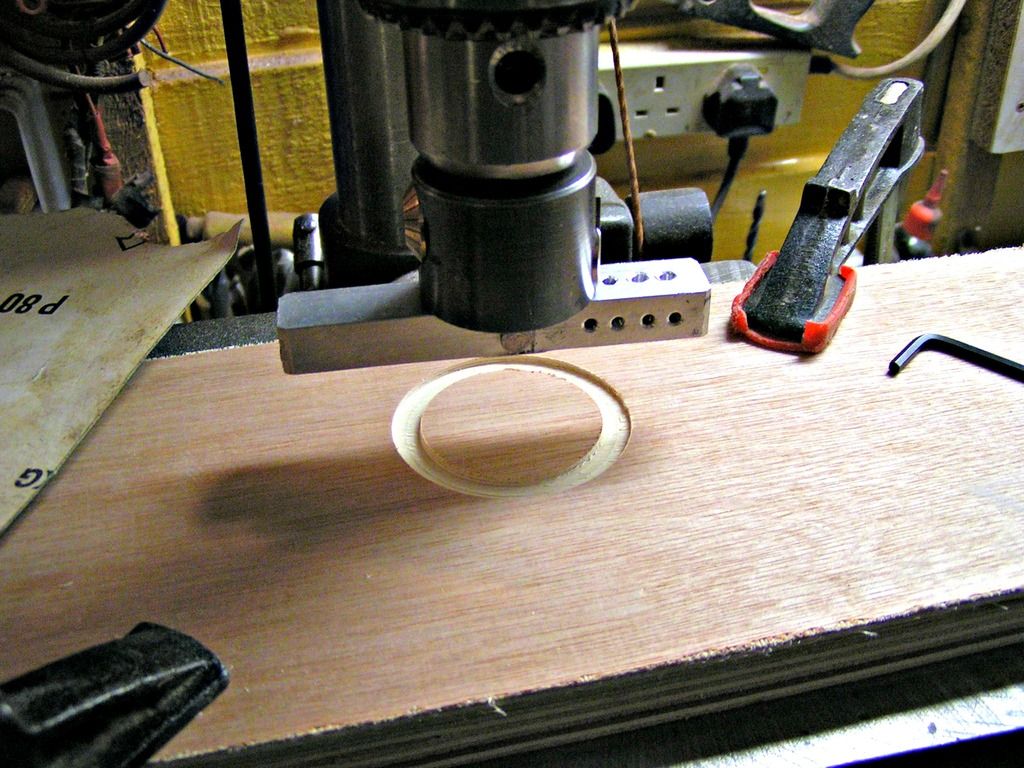

I recently remembered that I still had a couple left over..and I realised that they could be converted into adjustable rosette cutters..so today I had a go at one..dead easy to use just, pick a hole for the cutter near to the diameter required and turn adjuster dial to size..accurate to within .001" .. I tested it out on some cheap plywood scraps and it worked great...For me this is the best one yet...I wish I'd thought of it before...next i'll try it out on the new Concerts.

The Boring Head.

The cutter bar.

Fitted in boring head.

In Action.

And here's Part 3 http://s219.photobucket.com/user/shiregreenbod/media/4620d098.pbw.html

I recently remembered that I still had a couple left over..and I realised that they could be converted into adjustable rosette cutters..so today I had a go at one..dead easy to use just, pick a hole for the cutter near to the diameter required and turn adjuster dial to size..accurate to within .001" .. I tested it out on some cheap plywood scraps and it worked great...For me this is the best one yet...I wish I'd thought of it before...next i'll try it out on the new Concerts.

The Boring Head.

The cutter bar.

Fitted in boring head.

In Action.

Last edited: