Timbuck

Well-known member

I was wondering how others radius the corner on binding .. I use a file, scraper, and sand paper,..is there a tool that can make this job easier?

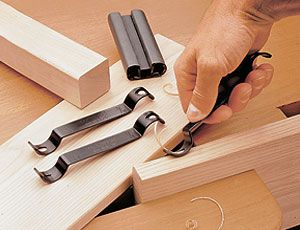

I see that they are in stock at Axminster Tools here in the UK http://www.axminster.co.uk/veritas-cornering-tool-kit-510441 so I ordered a set.. For bracing ? I never thought of that..Good idea.I use them for brace radiating for which they perform brilliantly but must be kept sharp. Never thought of using them for the edges.... and yes, they are very easy to mess up. The design is quite critical.

I'm refering to the the sharp edge on the binding I prefer it rounded off like this...This is not one of mine by the wayI just want to make sure, so I can learn, are you discussing the inside corner radius for relief which would yield a better fit, or the outside radius for the looks and comfort?

Yes I do that as well ..and on the nut.But, does anyone radius the INSIDE corner that sits in the binding channel? This is common practice in metalwork and engineering to get a better fit, since you can never get a perfectly square cut. I'm only talking about a radius of maybe 0.5mm or so here btw.