You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bender Mods

- Thread starter Timbuck

- Start date

leonel_elguti@hotmail.com

Active member

It looks like it'll work fine. Probably it'll even improve the waist radius to get an even smoother joint of the three radius and the

fluidity of curves at the transitions while changing from one radius to another (I don't know if that makes sense in english...).

Anyway! It'll work surely, Mr. Timbuck. Aloha!

fluidity of curves at the transitions while changing from one radius to another (I don't know if that makes sense in english...).

Anyway! It'll work surely, Mr. Timbuck. Aloha!

sequoia

Well-known member

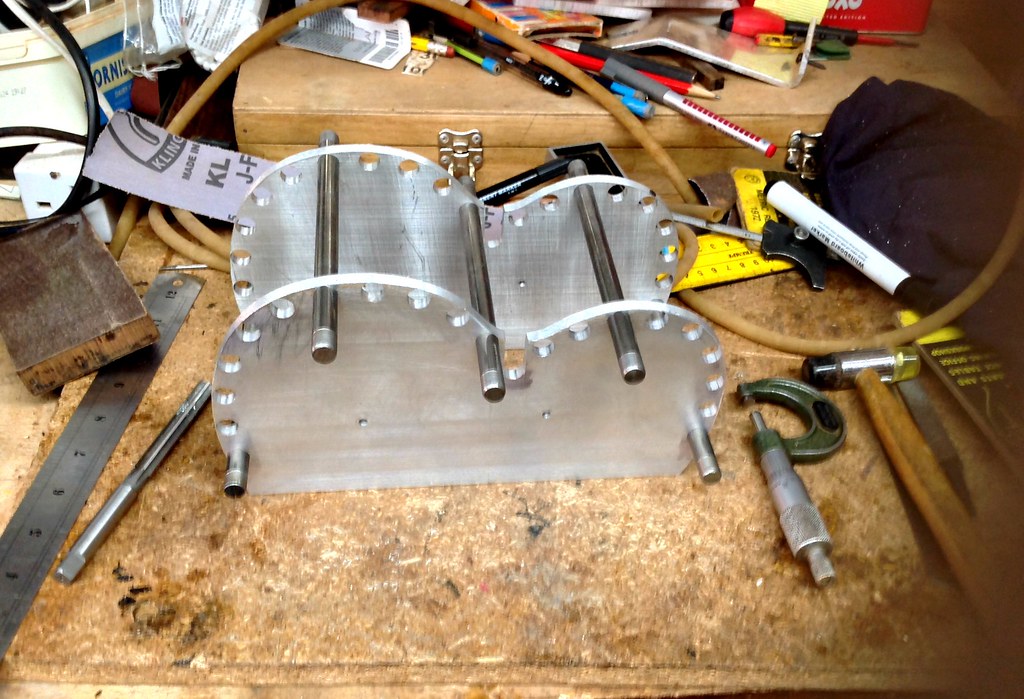

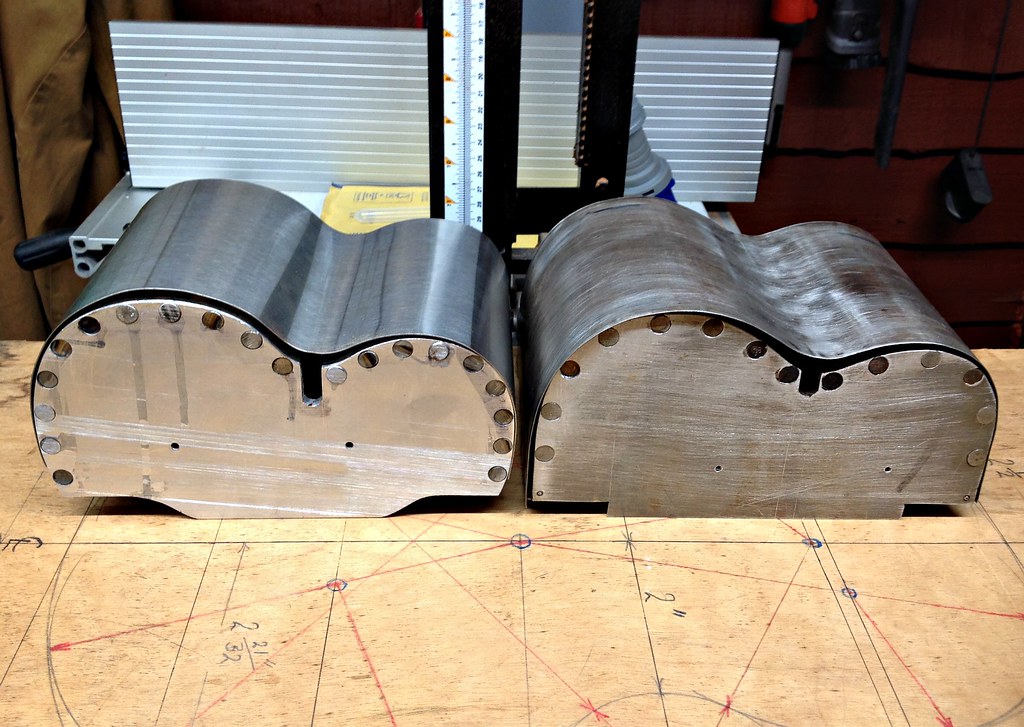

Im upgrading my Foxy type bender ..I'm making a new soprano side bending former ..It looks a bit odd shaped co's I'm trying this time to compensate for the spring back I get with mahogany.

View attachment 111468

I've always wanted to make a compensated bender but never get around to it... Interestingly, when the Wright brothers were making their first airplane wing they encountered problems with springback too. It puzzled them. We are not alone.

Timbuck

Well-known member

Coming along nicely...20 10mm rods to hold the heat, the old one had only 14..I recon this will cost me about 70 quid when it's done but it will be worth it if I can reduce the hand bending.....The hardest bit is done now "drilling and reaming the holes so that they are just flush with the rim"

IMG_1017 by Ken Timms, on Flickr

IMG_1017 by Ken Timms, on Flickr

IMG_1017 by Ken Timms, on Flickr

IMG_1017 by Ken Timms, on Flickr

Last edited:

sequoia

Well-known member

You really do like working with metal Ken. Beautiful.

Timbuck

Well-known member

Working with wood is just the same as working with metal..only you make more progress with wood..My Dad told me that

*EDIT* Anyone who is considering making one of these bender formers..remember to make the profile to the inside measurments of the uke (not the outside) plus the thickness of the steel slatt that goes under the sides while bending .. if using a heater blanket under the side piece allow for the thicknes of that as well..I know it's common sense but ??

*EDIT* Anyone who is considering making one of these bender formers..remember to make the profile to the inside measurments of the uke (not the outside) plus the thickness of the steel slatt that goes under the sides while bending .. if using a heater blanket under the side piece allow for the thicknes of that as well..I know it's common sense but ??

Last edited:

mikeyb2

Well-known member

Keep the pictures coming Ken, it'll be interesting to see how this develops.

Timbuck

Well-known member

Keep the pictures coming Ken, it'll be interesting to see how this develops.

I started a thread a couple of years back showing how i did this on a concert size bender .. it can be seen from page 6 onwards...only Photobucket killed all the pics with their ransom demands..but there is a fix you can download so that you can view them all again..The thread is here https://forum.ukuleleunderground.co...ake-some-concert-size-Ukes&highlight=concerts

mikeyb2

Well-known member

Thanks Ken, I'll check that out.

Timbuck

Well-known member

Beau Hannam Ukuleles

Well-known member

Nice Ken!

Is there a way you calculate how much tighter to make the mold for the spring back or do you just give it 1"tighter curve if it springs back 1"??

Is there a way you calculate how much tighter to make the mold for the spring back or do you just give it 1"tighter curve if it springs back 1"??

leonel_elguti@hotmail.com

Active member

We all have to trust the new one will be even more accurate onto the vintage Martin waist and radius than the older one. In Ken we trust (? Hahaha... Anyway it's a fact that I (and I dare to say we all) think there's a positive reason for you to upgrade the device. Hope this will result in the same good quality (or better) Soprano uke!

Timbuck

Well-known member

Nice Ken!

Is there a way you calculate how much tighter to make the mold for the spring back or do you just give it 1"tighter curve if it springs back 1"??

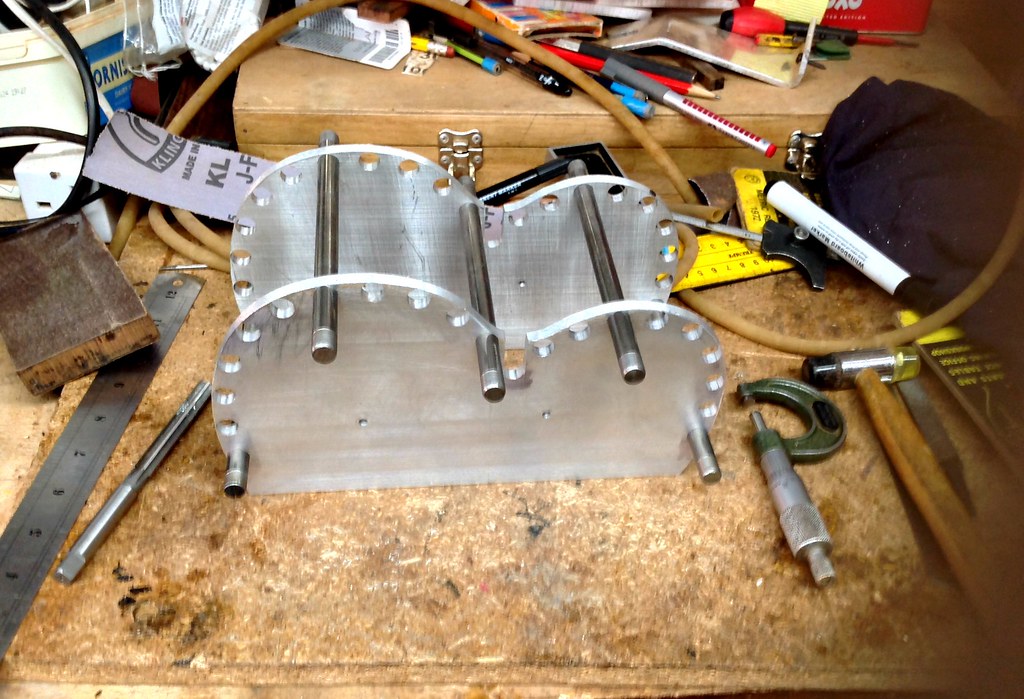

Over the past few months I have been taking a lot of notice of the main areas that i'm getting the spring back, mainly the waist and the area where the butt joints are ..The butt ends came out flat co's that was the shape of the former , the new former is now rounded at the ends..but the waist was springing back approx 1/4" so I increased the waist shape by an extra 1/4" deeper which should come out OK ..Thats if the sides don't break :uhoh: also there is a flat spot just a bit south of the waist on the lower bout so I added a bit on in that area ...Most likely I will still have to adjust a bit by hand on the hot pipe , but not as much as i have been doing

Here is the old one showing the areas that I needed to adjust.

IMG_1034 by Ken Timms, on Flickr

IMG_1034 by Ken Timms, on Flickr

Last edited:

mikeyb2

Well-known member

If anyone hasn't seen this video, it might be of interest regarding springback. https://www.youtube.com/watch?v=1qrQn84kVIk

Pete Howlett

Well-known member

Matthias Wandel in his much mocked (here) how to build a ukulele series shows how he calculated springback using math.... I don't get springback...

sequoia

Well-known member

I don't get springback...

Never? Not even a little bit?

Timbuck

Well-known member

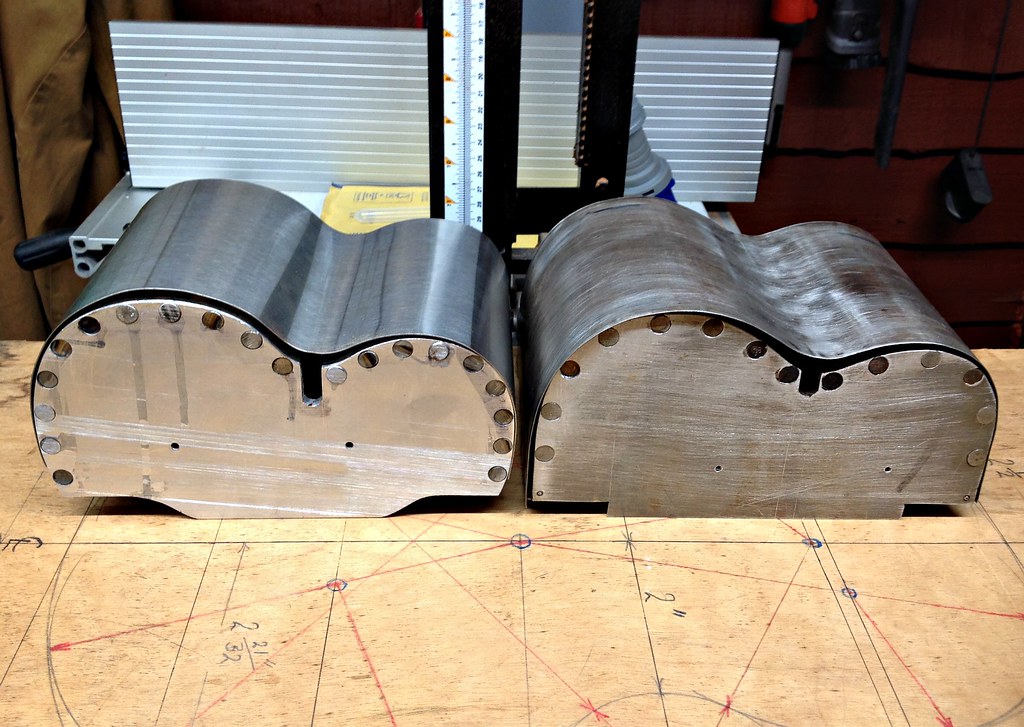

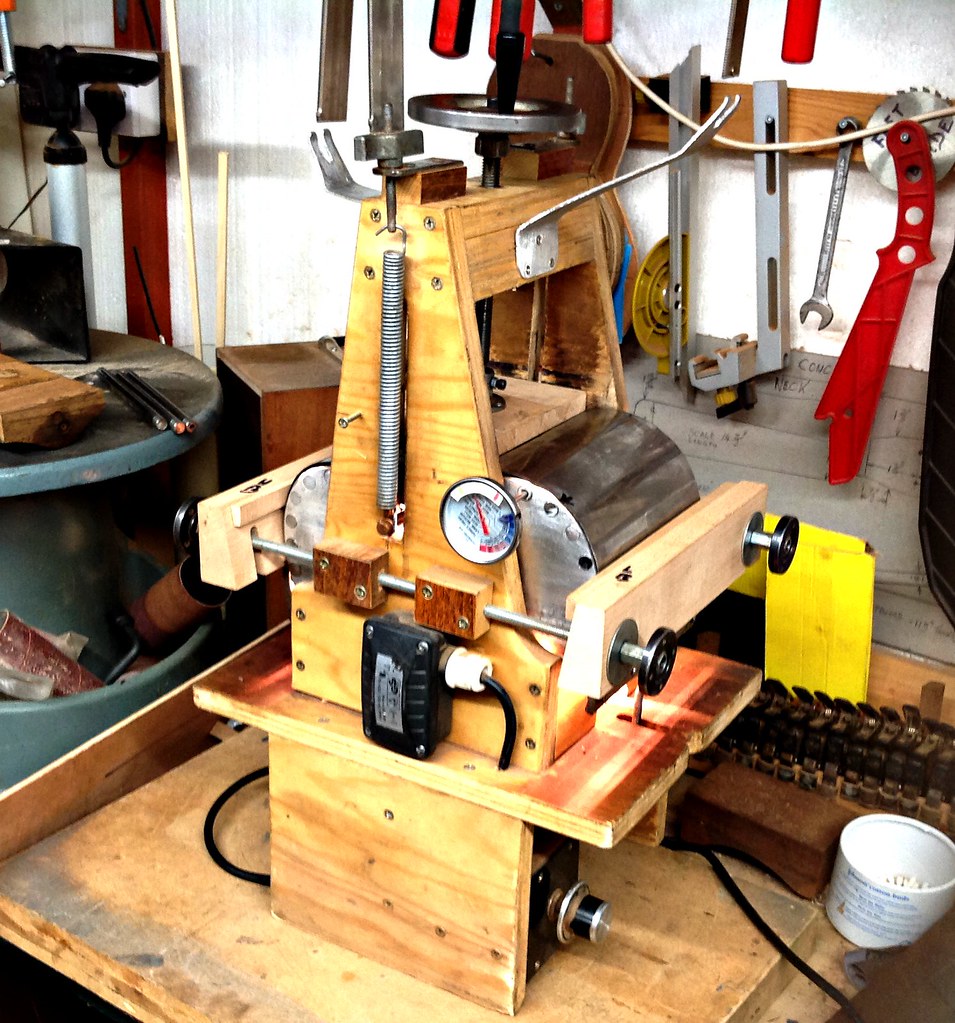

I got the mods finished today and before I quit for the day I thought I'd give it a test...switched on the Foxy to heat up..then got a pair of dodgy looking sides, I've been saving these co's they are very highly figured sapele ,you could say curly..and looked as if they would be very dificult to bend, so ideal for this first test...If these turn out ok anything will.

I wetted them wrapped them in aluminium foil and as the Foxy temperature reached almost "too well done" on the kitchen Meat thermometre I put them in...As I wound down the top caul and started the bending of the waist something went bump ??:uhoh: I immediately thought "they have broke..so disheartened i disided to carry on and see how the rest of the bending had gone and switched off the power at about 300 C...After about 15 minutes it had cooled down enough to get the sides out..first thing I noticed before I removed the foil was how tight the waist bend was and when the foil was removed,to my great amazement the waist wasnt cracked or broken at all, but when I put the sides in the mould it was slightly overbent (now I need springback in that spot) That I can easilly fix... all the rest of the bends were spot on and I'm now a happy bunny... I'll supply some pics tomorrow as i'm now relaxing :cheers:

That I can easilly fix... all the rest of the bends were spot on and I'm now a happy bunny... I'll supply some pics tomorrow as i'm now relaxing :cheers:

I wetted them wrapped them in aluminium foil and as the Foxy temperature reached almost "too well done" on the kitchen Meat thermometre I put them in...As I wound down the top caul and started the bending of the waist something went bump ??:uhoh: I immediately thought "they have broke..so disheartened i disided to carry on and see how the rest of the bending had gone and switched off the power at about 300 C...After about 15 minutes it had cooled down enough to get the sides out..first thing I noticed before I removed the foil was how tight the waist bend was and when the foil was removed,to my great amazement the waist wasnt cracked or broken at all, but when I put the sides in the mould it was slightly overbent (now I need springback in that spot)

Last edited:

Timbuck

Well-known member

Here are some pic's

The new former alongside the old

IMG_1128 by

IMG_1128 by

In the bender cooking the sides

[url=https://flic.kr/p/27RQuA5] IMG_1138 by

IMG_1138 by

And the result

[url=https://flic.kr/p/27RQvxf] IMG_1144 by https://www.flickr.com/photos/150702140@N02/

IMG_1144 by https://www.flickr.com/photos/150702140@N02/

The new former alongside the old

IMG_1128 by

IMG_1128 by In the bender cooking the sides

[url=https://flic.kr/p/27RQuA5]

IMG_1138 by

IMG_1138 by And the result

[url=https://flic.kr/p/27RQvxf]

IMG_1144 by https://www.flickr.com/photos/150702140@N02/

IMG_1144 by https://www.flickr.com/photos/150702140@N02/

Last edited:

leonel_elguti@hotmail.com

Active member

Wow! It looks like it will work perfectly. The wood used for the sides looks pretty! Regards!

Timbuck

Well-known member

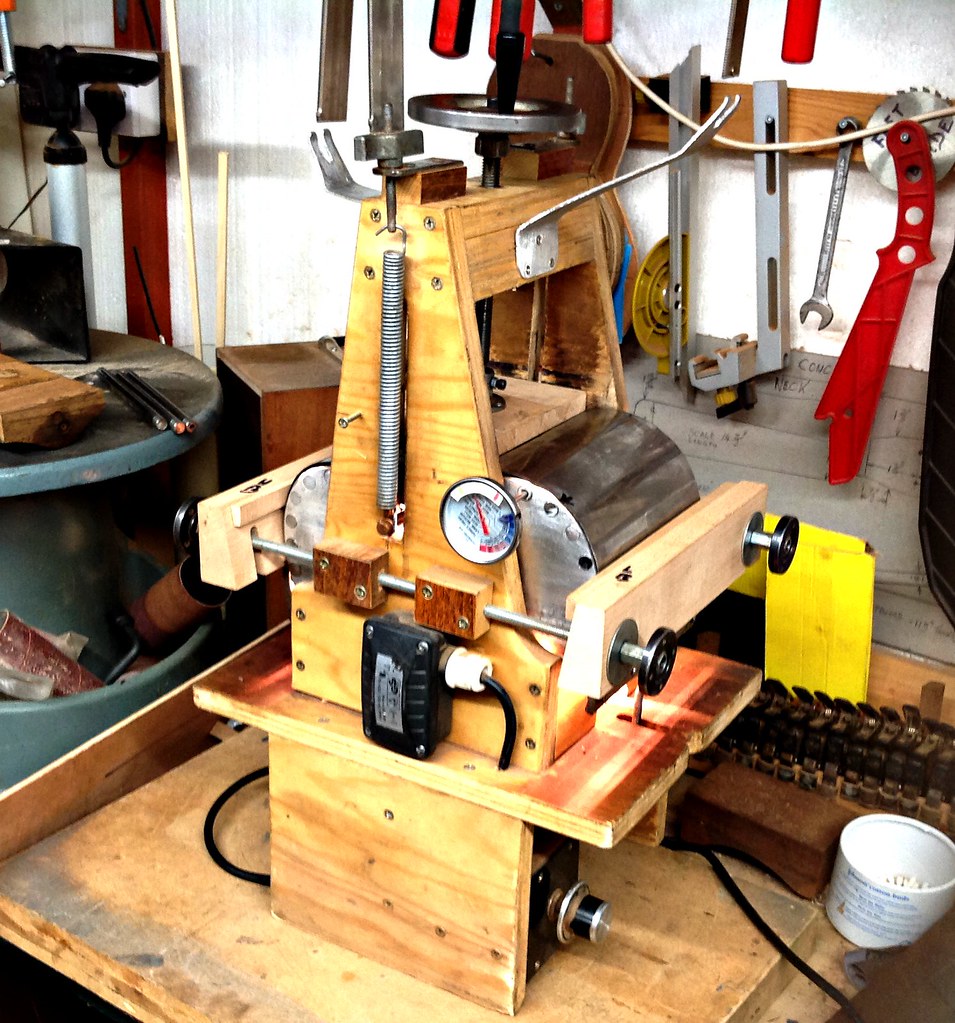

Bent another set today..and put them together ..This is much better now, they are trimmed and glued to the end blocks straight from the bender with no further heat adjustment needed...So that's taken a lot of mental stress out of the build.

IMG_1164 by https://www.flickr.com/photos/150702140@N02/

IMG_1164 by https://www.flickr.com/photos/150702140@N02/

IMG_1164 by https://www.flickr.com/photos/150702140@N02/

IMG_1164 by https://www.flickr.com/photos/150702140@N02/

Last edited:

Similar threads

- Replies

- 2

- Views

- 330

- Replies

- 5

- Views

- 1K

- Replies

- 6

- Views

- 576