Timbuck

Well-known member

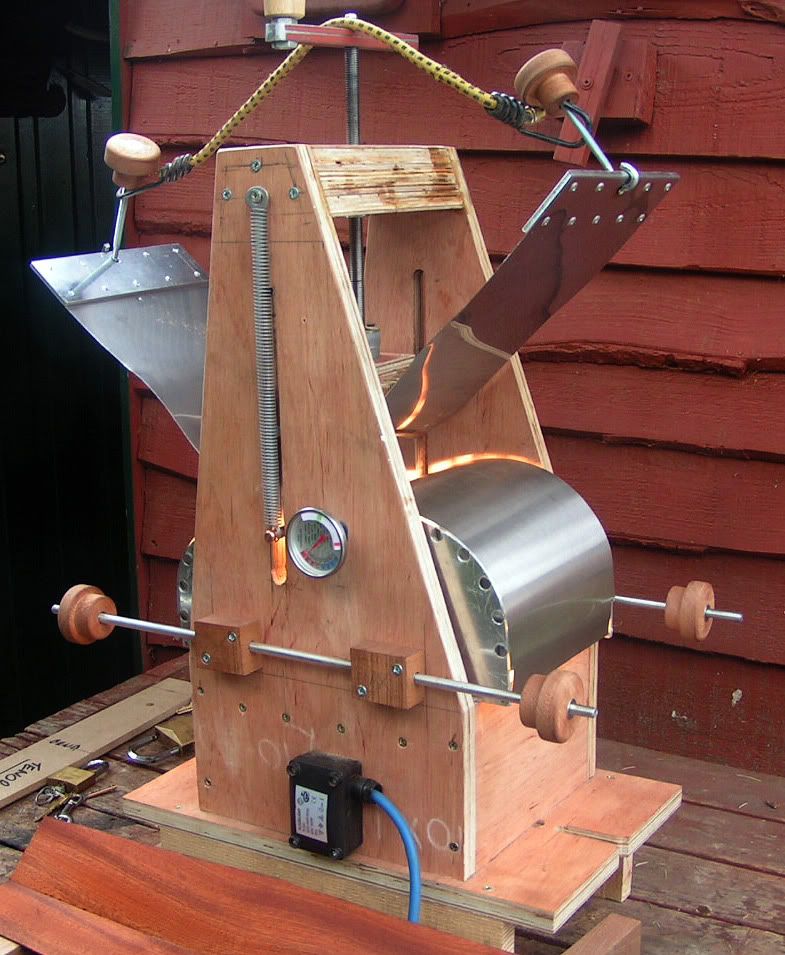

This is my Bender in use for the last time before I refurbish it..I recon it's bent about 90 pairs of soprano sides to date ..

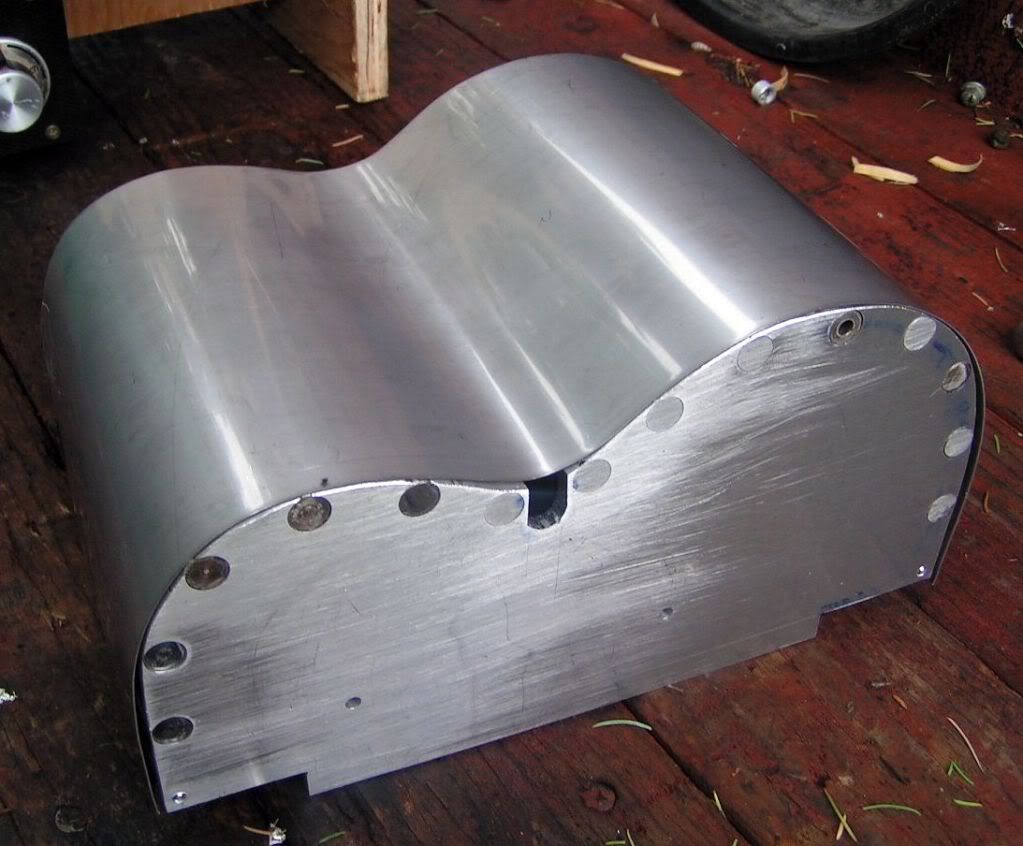

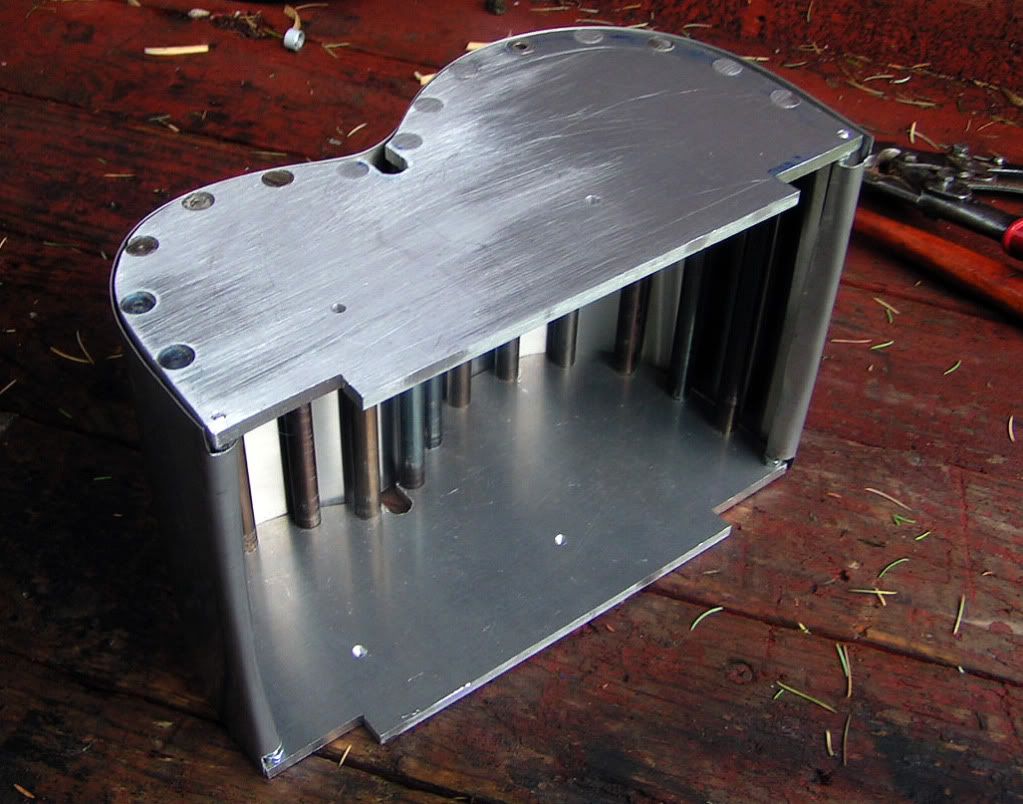

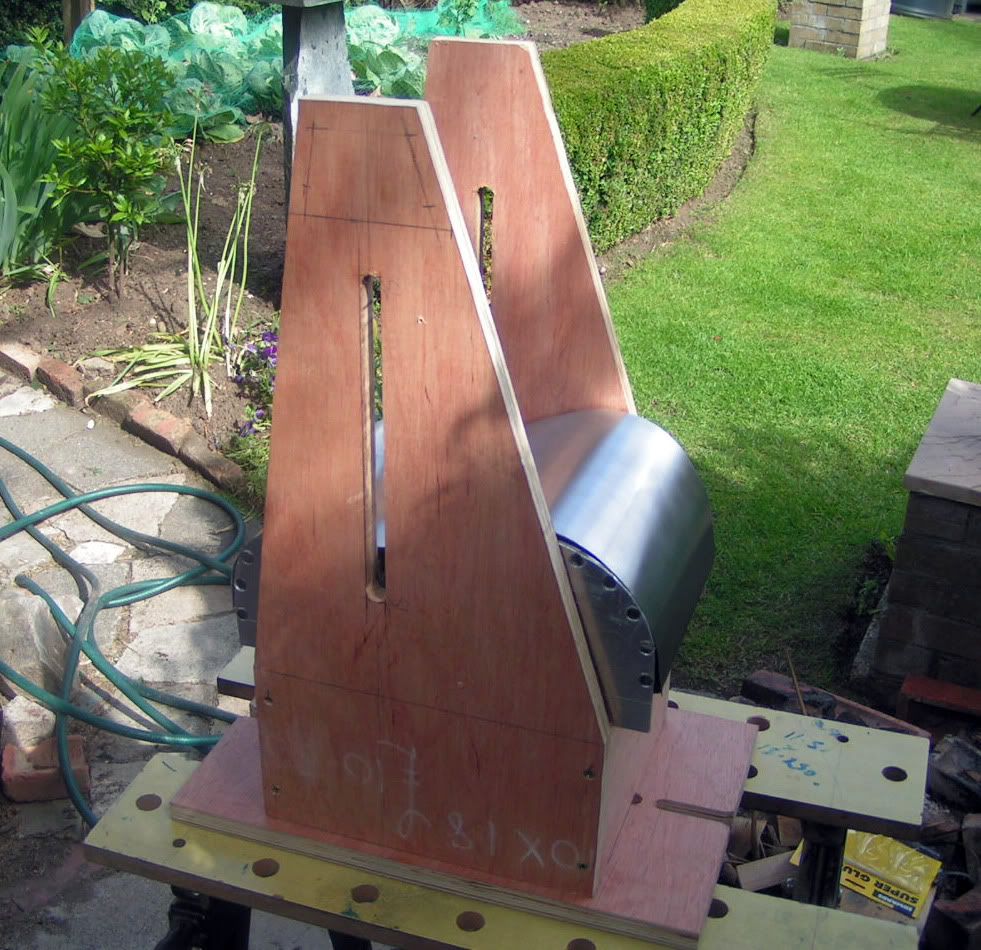

and the heat generated into the steel heat containment rods, has chard away the woodwork causing the form plate and workpiece to drop in the area of the uke waist and it is now producing sides that have to be adjusted on the hot pipe.. I intend replacing the damaged parts with Aluminium plate...Here is short slideshow of the damage..Click on the small image to view.

and the heat generated into the steel heat containment rods, has chard away the woodwork causing the form plate and workpiece to drop in the area of the uke waist and it is now producing sides that have to be adjusted on the hot pipe.. I intend replacing the damaged parts with Aluminium plate...Here is short slideshow of the damage..Click on the small image to view.

Last edited: