zdiver7

Well-known member

Hey everyone!

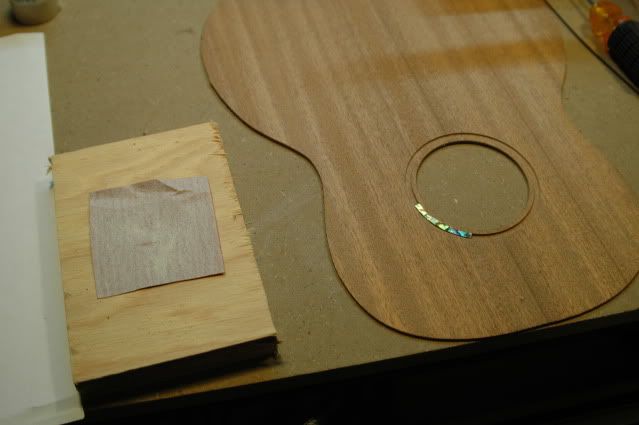

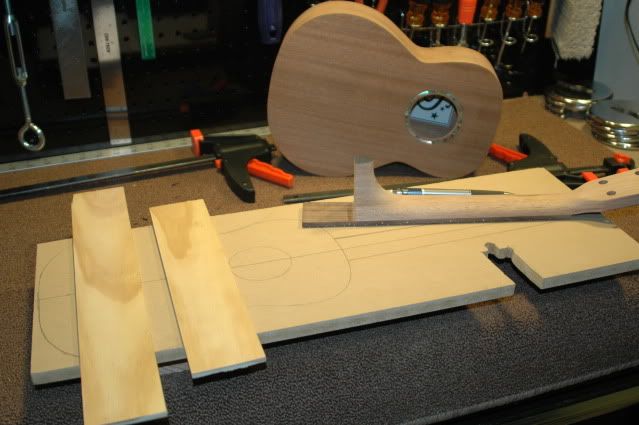

Since it seems that there are a few of us building the Stew-Mac Tenors right now, I thought I would share some pics of my progress...

Currently, I am in the process of final sanding and prep for finishing. I need to order my finish still...I am going to go with a Zpoxy grain fill and KTM-9 waterbased finish. I may still go with nitro, but right now I am thinking that I will order the H20based

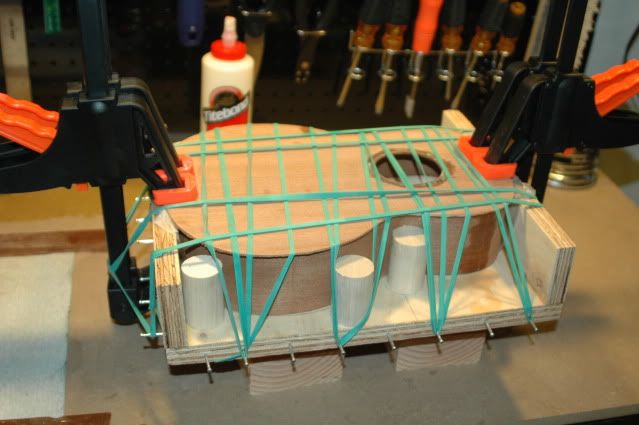

A few of you were asking about the Stew-Mac building jig...you can see in some of the pics what I did to mine, I think it helped keep the sides and body still during the process, and was very quick and easy to build.

Sooo... first are some pics of the neck and tail blocks, along with the linings getting glued in. For those who were asking about the building jig, note that instead of the L-brackets, I used 1" dowels cut to necessary length and placed them at the waist, above and below the lower bout...no problems with a wiggly body or sides!

Since it seems that there are a few of us building the Stew-Mac Tenors right now, I thought I would share some pics of my progress...

Currently, I am in the process of final sanding and prep for finishing. I need to order my finish still...I am going to go with a Zpoxy grain fill and KTM-9 waterbased finish. I may still go with nitro, but right now I am thinking that I will order the H20based

A few of you were asking about the Stew-Mac building jig...you can see in some of the pics what I did to mine, I think it helped keep the sides and body still during the process, and was very quick and easy to build.

Sooo... first are some pics of the neck and tail blocks, along with the linings getting glued in. For those who were asking about the building jig, note that instead of the L-brackets, I used 1" dowels cut to necessary length and placed them at the waist, above and below the lower bout...no problems with a wiggly body or sides!