Timbuck

Well-known member

Having a workshop with a "Milling Machine" can come in handy sometimes, when you can make things that are just not available anywhere else.

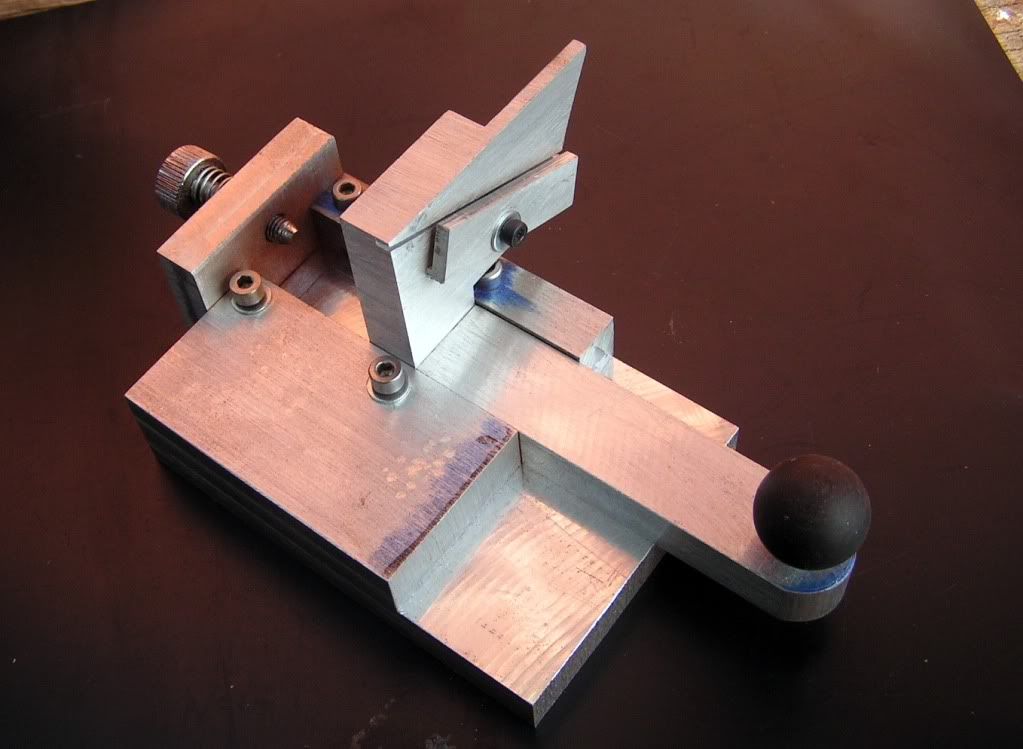

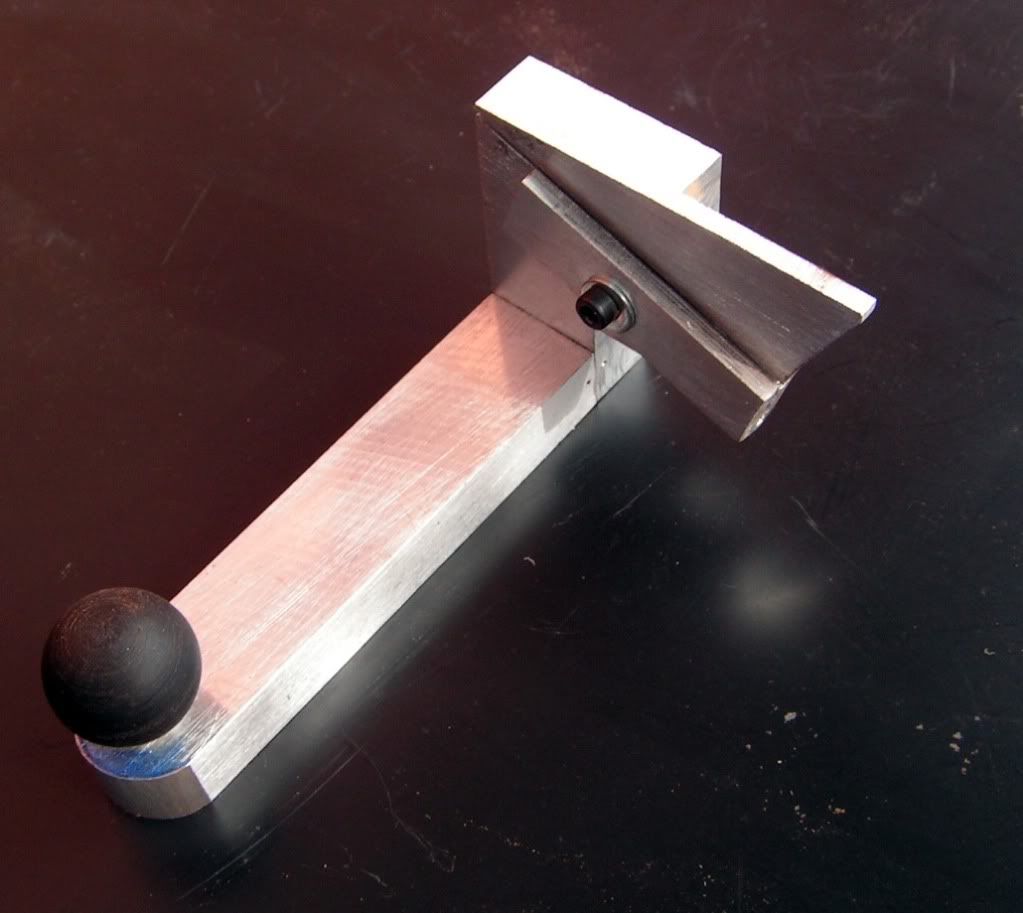

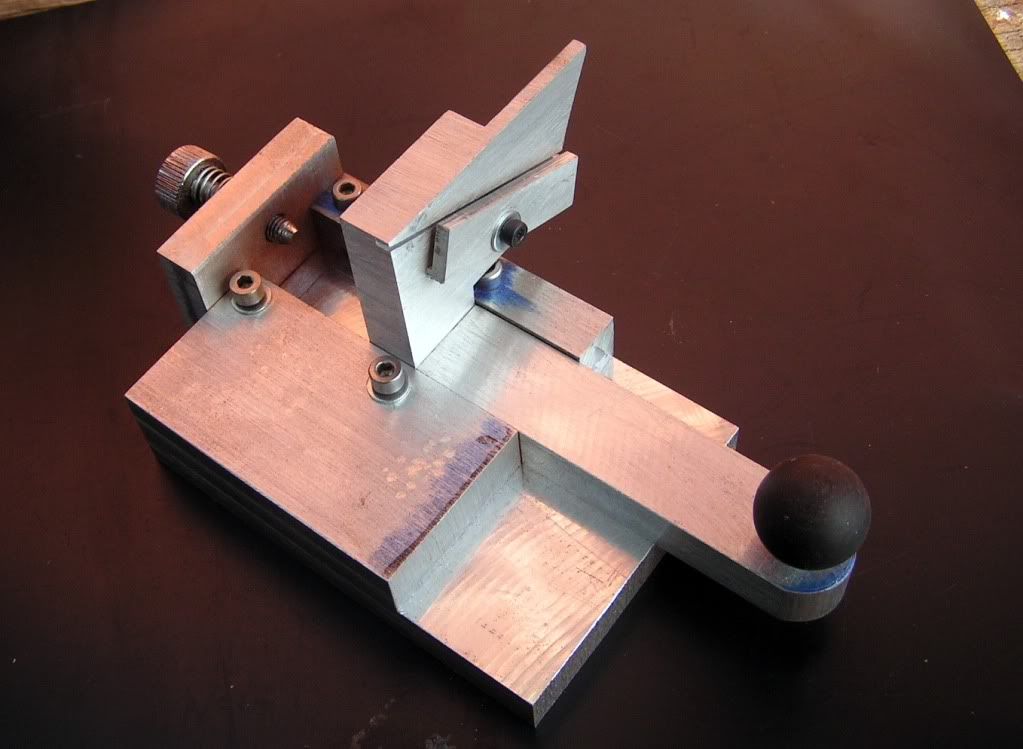

With the small thin type fret wire that I use.. I've found trimming the tangs at the end with wire cutters is a fiddly job and it distorts the wire a bit...and under close inspection it dosn't do a very neat job ...So I pinched an idea from "Chuck"

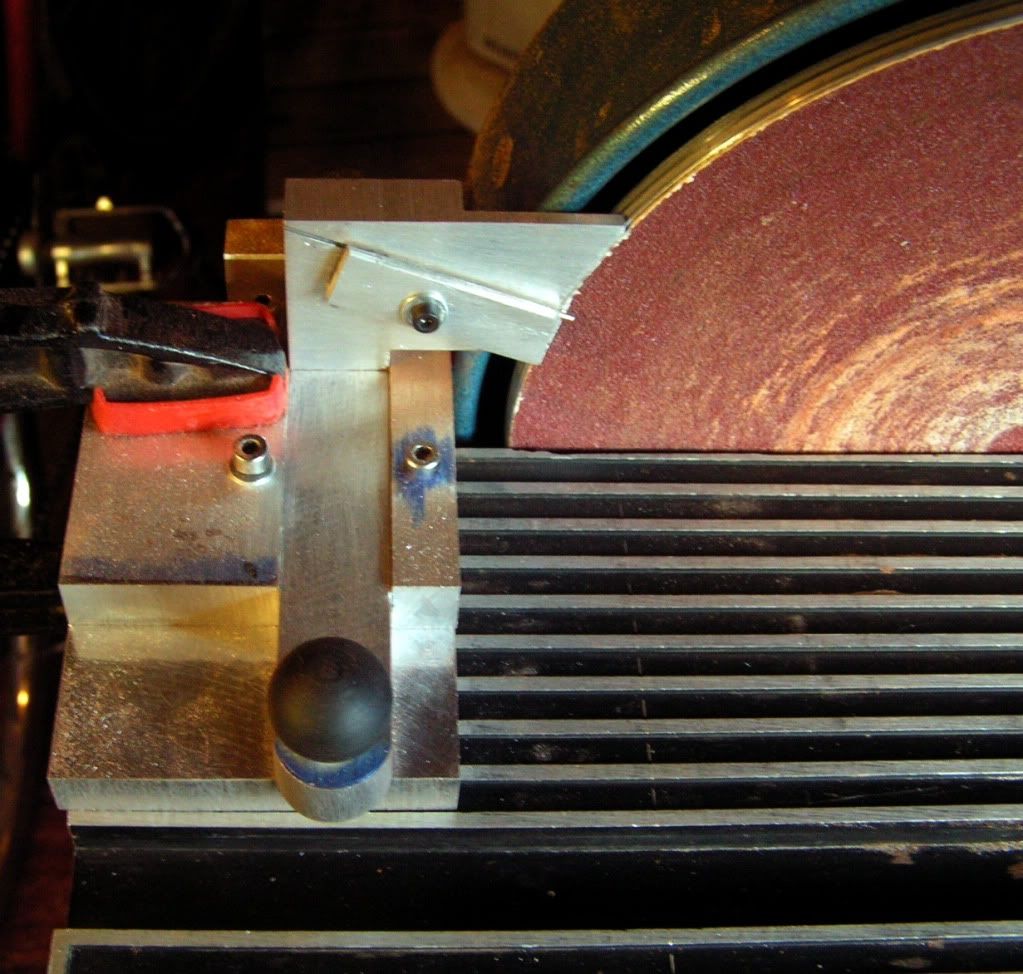

...So I pinched an idea from "Chuck" ..Good old "Chuck" found a way of doing this job on a mini grinder...So I took the idea and poshed it up a bit and came up with this...It can be used on a disc/belt sander or a pedestal grinder or whatever...Once set up it works superdooper and every one comes off the same.

..Good old "Chuck" found a way of doing this job on a mini grinder...So I took the idea and poshed it up a bit and came up with this...It can be used on a disc/belt sander or a pedestal grinder or whatever...Once set up it works superdooper and every one comes off the same.

With the small thin type fret wire that I use.. I've found trimming the tangs at the end with wire cutters is a fiddly job and it distorts the wire a bit...and under close inspection it dosn't do a very neat job