Timbuck

Well-known member

On the Stewmac site is a video of one of these in action..I thought to myself I may buy one of those for my shed..but when I saw the price I had to think again..it costs far to much for my budget..if I spent that much on it plus postage and taxes to the UK..I'd have to move into the bunker with Gaddafy to get away from Mrs Timbuck's wrath

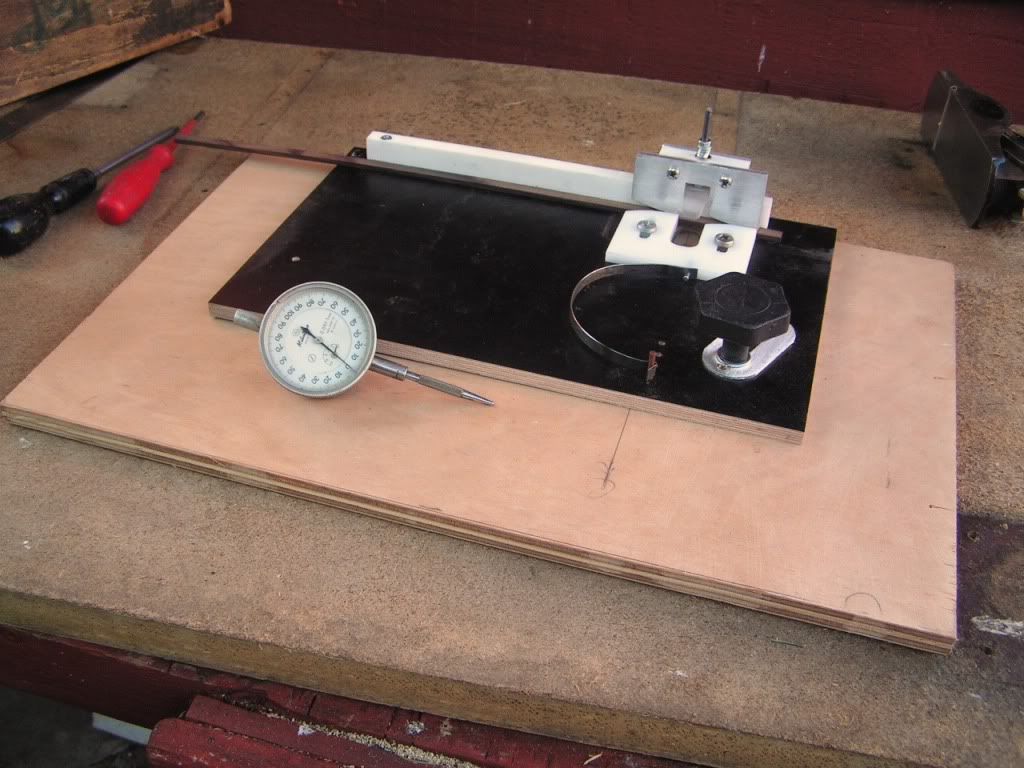

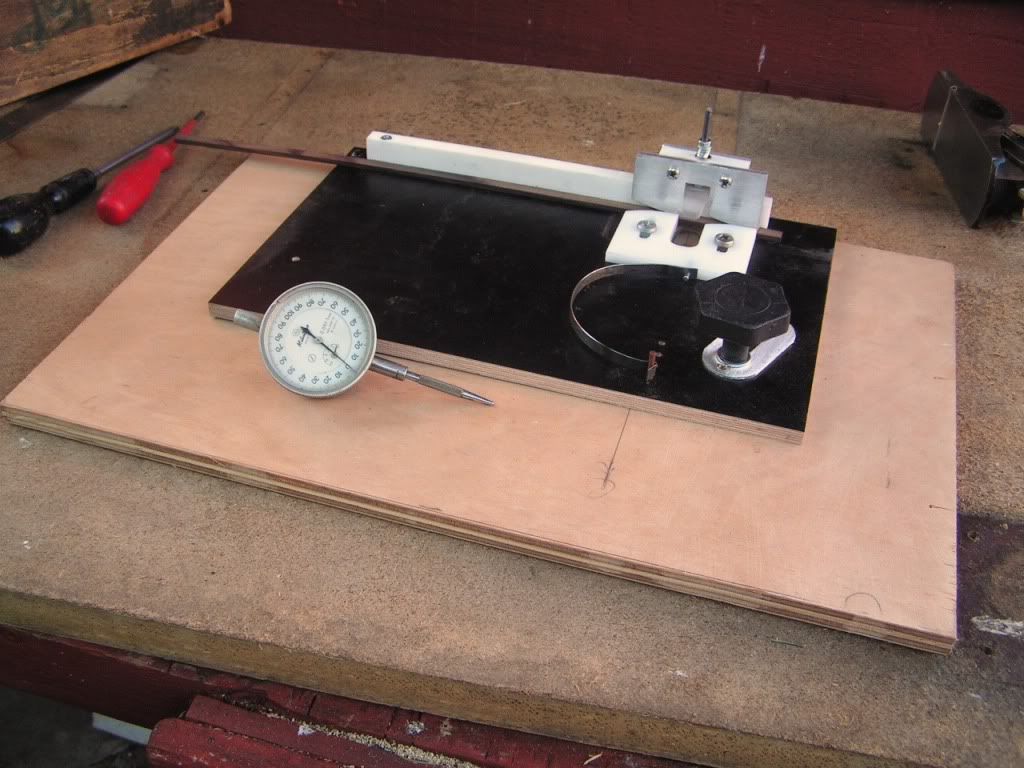

So I studied the Video again..then went into my scrap box and with some Corian worktop bits, Plywood, aluminium scrap, and a broken piece of spring from my drill press,...I made this.

It wasn't too difficult ..and tomorrow i'll fit the dial gauge and test it out on the Table Router.

..and tomorrow i'll fit the dial gauge and test it out on the Table Router.

So I studied the Video again..then went into my scrap box and with some Corian worktop bits, Plywood, aluminium scrap, and a broken piece of spring from my drill press,...I made this.

It wasn't too difficult