BR Ukuleles

Well-known member

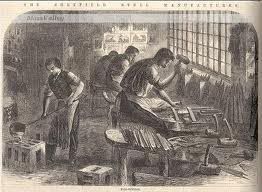

A mate sent me this link to Liogier Hand Stitched Rasps and found it really interesting. Watch the video for some insight as to why those tools cost what they do.

A mate sent me this link to Liogier Hand Stitched Rasps and found it really interesting. Watch the video for some insight as to why those tools cost what they do.

Probably by immersing it in an acidic chemical of some sort, etching the metal and sharpening the tips of the teeth. That's how files are usually sharpened.The amazing thing about the Dragon files is that they'll resharpen them for a small fee. Now howzat done?!!!!!!!

As beautiful as those rasps are, teeth cutting seems a tedious and monotonous process - not an appropriate manual work in the current era. The hand work of making those rasps seems like a job better suited to an automated process for high volume.