joejeweler

Well-known member

- Joined

- Jul 7, 2011

- Messages

- 538

- Reaction score

- 0

Cordoba 25CK IS LAMINATED! Maybe I Shouldn't Believe My "Lying" Eyes! Geeze......

Forget all the previous discussions about whether the Cordoba 25CK

ukulele is real KOA or "Acacia" wood,......It's NEITHER! I'm SO P*ssed! @$%^&*#@

Here is their website where they spout all the same corporate BS we've grown a bit used to. Will it never end???

They clearly state on their website this model is SOLID koa. (acacia to the rest of us since it's not grown in Hawaii)

http://www.cordobaguitars.com/82.php

My reciept from Guitar Center also states it a solid koa ukulele. The hang tag (that GC kept)

also stated it to be a solid koa uke,...

.....and it all means nuthing when it's really a laminated imposter!

EDITED to add: See my post #18 in this thread, wherein i describe why i think the top might very well be of solid one piece construction. The back and sides most definately aren't!

Unless i am the unluckiest buyer who just happened to buy their only laminated goofup,....i feel a bit raped in the

wallet. (but the lying part is worse)

Laminated ukes sell for under $100.00 and sometimes a lot less. With tax this was just over $300.00, and

yesterday i just recieved a Uke-Crazy hard case for it,....at $70.00

I returned the gig bag it came with and recieved a $25 plus credit on my CC, and that brought the uke cost

to $255.00 plus tax. The hard case not included in that figure.

(the Model 25 "CK" means Concert/Koa, and they make a Soprano and Tenor of this also, probably the same BS!)

I bought it as a travel uke, so as not to have a really good ukulele subject to theft,....and maybe bring camping and to the beach. I'm pretty handy and have always done my own setup and some repairs on guitars.

I figured i could tweak this uke along the way, and make it a whole lot better sounding given the fact it was supposed to be "SOLID" Koa! (insert acacia wood here if you will, but i already knew THAT!)

You might remember my post where i replaced the ill-fitting saddle with a hard african ivory one from Bob Colosi, and that cured the major intonation problems i was having. It also improved the overall tone and volumn,. but was still thin and with a muted voice. Here's that thread with pics: http://www.ukuleleunderground.com/f...Ivory-Saddle-Cures-Intonation-Volumn-amp-Tone

Tonight i decided to put a sound port in it, as in the past it has always allowed the player to hear much more of

what an audience might. I've done 4 already,....all on acoustic guitars but basically the same process.

Imagine my surprise when, after making a cardboard oval pattern and tracing it over the lower bout with a magic marker, i began to cut into the wood and quickly saw a MUCH lighter wood underneath! :wtf:

After i discovered the laminated side, i took a few minutes to calm down before i could go back to work. No backing out now anyway!

I used the lower bout because my intent was to be able to more easily remove the top brace going from near the soundhole and going to the tail block. It's actually a better spot on a ukulele, because the hole ends up closer to your ear than would happen with a soundport on the upper bout. A noted luthier also places his acoustic "flutes" into the

bevel on the lower bout, because it's the more acoustically "active" part of the body.

(Kevin Ryan with his multi-ported version along the armrest bevel)

After rough cutting inside my magic marker line and removing the section, i went back in with a small sanding drum mounted in my Foredom flexable shaft machine to smooth the wood out to the marker line. Carefully hand sanding in finer grits completed the soundport.

The port helped some to get more sound up to my ear, but the brace removal was the other reason i put the port in, and that came out next. I slightly altered a thin kitchen knife to create a small bend in it, and taper the end to a chisel type edge to get under the brace and carefully pry the brace off. This brace went over the bridge pad, bit fortunately

was not glued to the pad. A few minutes later the brace was out, and the uke sounded about 40% louder and much fuller. Still not like a high end ukulele by the better builders, of course, but still a significant improvement from where we started.

.......i can only imagine what it might have sounded like IF the woods used were truly solid! I suspect the top is much the same, but i'm not planning on cutting into that. Virtually certain it's laminated also.......

One last thing i plan on getting done eventually is to slowly sand down and taper the bridge pad a bit. It looks to be about 2 mm thick, and approaches to about 1/2" of the kerfed linings. I'd like to get it to maybe 1 mm thick, and feather the ends back to at least an inch of the linings.

Anyway, here are some pics:

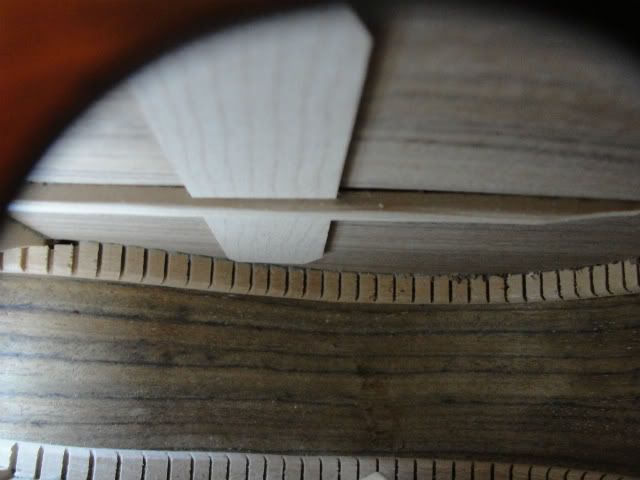

Here's the soundport, eventually i'll stain the inner edge to blend in and make the obvious 3 piece sandwich less obvious. I planned it's position to make the brace removal and future bridge pad thinning much easier.

A soundport access hole trumps working thru the main soundhole or removing the back.

....you can clearly see the laminated sections, where a lighter central wood is sandwiched between an outer and inner veneer of acacia wood. The upper 2 sections are more evident in the pic, but there is a 3rd lower darker wood lamination.

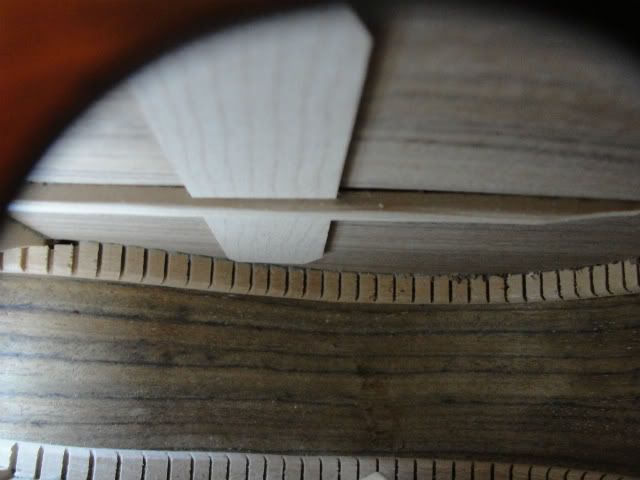

The wide brace is the bridge pad, the thinner one going

left to right is no longer there!

Forget all the previous discussions about whether the Cordoba 25CK

ukulele is real KOA or "Acacia" wood,......It's NEITHER! I'm SO P*ssed! @$%^&*#@

Here is their website where they spout all the same corporate BS we've grown a bit used to. Will it never end???

They clearly state on their website this model is SOLID koa. (acacia to the rest of us since it's not grown in Hawaii)

http://www.cordobaguitars.com/82.php

My reciept from Guitar Center also states it a solid koa ukulele. The hang tag (that GC kept)

also stated it to be a solid koa uke,...

.....and it all means nuthing when it's really a laminated imposter!

EDITED to add: See my post #18 in this thread, wherein i describe why i think the top might very well be of solid one piece construction. The back and sides most definately aren't!

Unless i am the unluckiest buyer who just happened to buy their only laminated goofup,....i feel a bit raped in the

wallet. (but the lying part is worse)

Laminated ukes sell for under $100.00 and sometimes a lot less. With tax this was just over $300.00, and

yesterday i just recieved a Uke-Crazy hard case for it,....at $70.00

I returned the gig bag it came with and recieved a $25 plus credit on my CC, and that brought the uke cost

to $255.00 plus tax. The hard case not included in that figure.

(the Model 25 "CK" means Concert/Koa, and they make a Soprano and Tenor of this also, probably the same BS!)

I bought it as a travel uke, so as not to have a really good ukulele subject to theft,....and maybe bring camping and to the beach. I'm pretty handy and have always done my own setup and some repairs on guitars.

I figured i could tweak this uke along the way, and make it a whole lot better sounding given the fact it was supposed to be "SOLID" Koa! (insert acacia wood here if you will, but i already knew THAT!)

You might remember my post where i replaced the ill-fitting saddle with a hard african ivory one from Bob Colosi, and that cured the major intonation problems i was having. It also improved the overall tone and volumn,. but was still thin and with a muted voice. Here's that thread with pics: http://www.ukuleleunderground.com/f...Ivory-Saddle-Cures-Intonation-Volumn-amp-Tone

Tonight i decided to put a sound port in it, as in the past it has always allowed the player to hear much more of

what an audience might. I've done 4 already,....all on acoustic guitars but basically the same process.

Imagine my surprise when, after making a cardboard oval pattern and tracing it over the lower bout with a magic marker, i began to cut into the wood and quickly saw a MUCH lighter wood underneath! :wtf:

After i discovered the laminated side, i took a few minutes to calm down before i could go back to work. No backing out now anyway!

I used the lower bout because my intent was to be able to more easily remove the top brace going from near the soundhole and going to the tail block. It's actually a better spot on a ukulele, because the hole ends up closer to your ear than would happen with a soundport on the upper bout. A noted luthier also places his acoustic "flutes" into the

bevel on the lower bout, because it's the more acoustically "active" part of the body.

(Kevin Ryan with his multi-ported version along the armrest bevel)

After rough cutting inside my magic marker line and removing the section, i went back in with a small sanding drum mounted in my Foredom flexable shaft machine to smooth the wood out to the marker line. Carefully hand sanding in finer grits completed the soundport.

The port helped some to get more sound up to my ear, but the brace removal was the other reason i put the port in, and that came out next. I slightly altered a thin kitchen knife to create a small bend in it, and taper the end to a chisel type edge to get under the brace and carefully pry the brace off. This brace went over the bridge pad, bit fortunately

was not glued to the pad. A few minutes later the brace was out, and the uke sounded about 40% louder and much fuller. Still not like a high end ukulele by the better builders, of course, but still a significant improvement from where we started.

.......i can only imagine what it might have sounded like IF the woods used were truly solid! I suspect the top is much the same, but i'm not planning on cutting into that. Virtually certain it's laminated also.......

One last thing i plan on getting done eventually is to slowly sand down and taper the bridge pad a bit. It looks to be about 2 mm thick, and approaches to about 1/2" of the kerfed linings. I'd like to get it to maybe 1 mm thick, and feather the ends back to at least an inch of the linings.

Anyway, here are some pics:

Here's the soundport, eventually i'll stain the inner edge to blend in and make the obvious 3 piece sandwich less obvious. I planned it's position to make the brace removal and future bridge pad thinning much easier.

A soundport access hole trumps working thru the main soundhole or removing the back.

....you can clearly see the laminated sections, where a lighter central wood is sandwiched between an outer and inner veneer of acacia wood. The upper 2 sections are more evident in the pic, but there is a 3rd lower darker wood lamination.

The wide brace is the bridge pad, the thinner one going

left to right is no longer there!

Last edited: