Timbuck

Well-known member

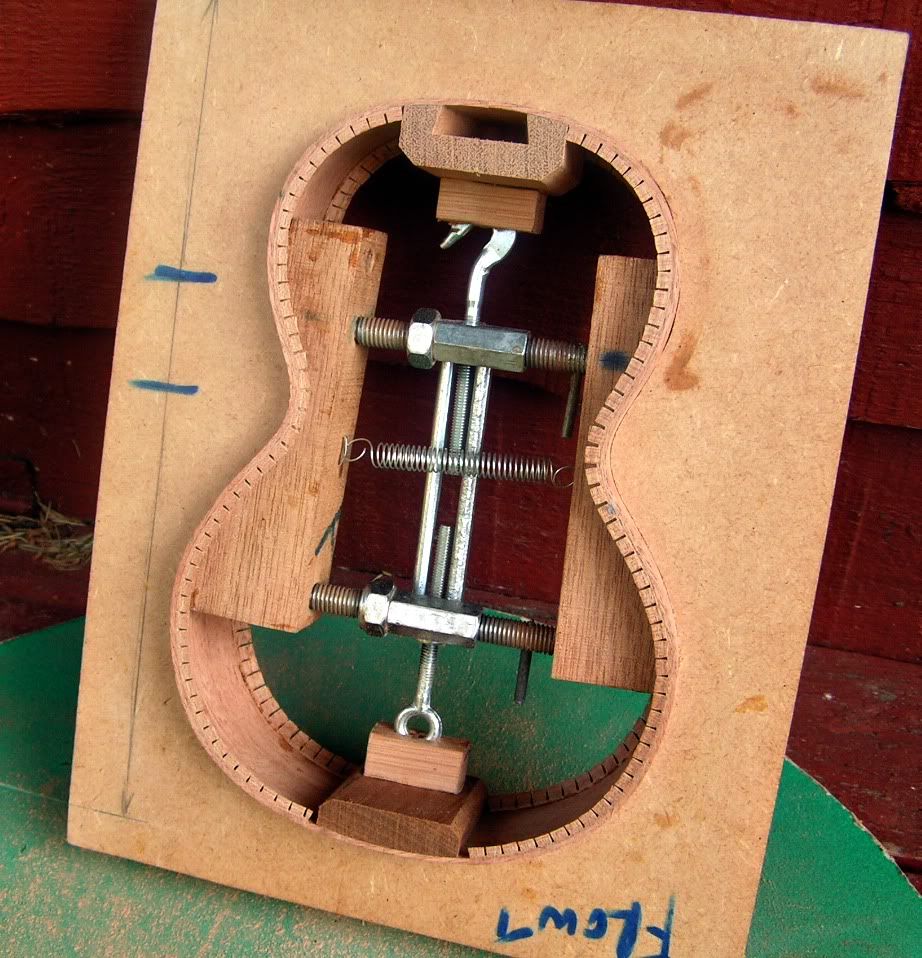

It's amazing how methods keep changing when building..for the last dozen or so Sopranos i've built, once I've fitted the end/neck blocks, I then transfer the assembly to this simple intermediate jig... it's clamped tightly in position... then all the sanding , fitting the linings, and radiusing etc: are done all in one setup top and back.. I find this method makes the job a lot easier...It's made from two pieces of MDF and its strong and light and easy to manouvere when sanding on the radius dish.

Afterwards it's transfered to the main mold for final assembly.

Afterwards it's transfered to the main mold for final assembly.