Timbuck

Well-known member

I spent a couple of hours today resawing a few sets..and I just found this on the web http://www.closegrain.com/2012/10/resawing-by-hand.html I'm glad I bought the bandsaw

Last edited:

I'm currently reading a marquetry book by Silas Kopf.

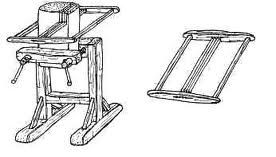

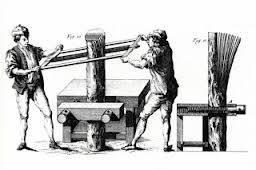

In it he talks of the French timbre merchants and specialised veneer resawers in the 1600's that cut all that exotic and very expensive tropical hardwood that was showing up from around the world by hand. They got to the point of being able to cut 2.3 - 2.5mm slices accurately using a method that is similar to the pit saw technique. Some of the line drawings of the time depict saws with multiple blades evenly spaced apart in order to cut more than one veneer at a time.

I've seen some current YouTube videos of vertical gangsaws like that which just hum right along. Setting them in frame with high tension allow seem to let them use thin saw blades and agressive pitches. Quite impressive to watch. Don't know how it would work at instrument thicknesses.

I was starting to build a large (40"-48") frame saw using a 3 TPI x 1" used bandsaw blade for resawing but found that a lot of people were having trouble with blade wander. Need to revisit that project.

One thing going for a handsaw is the wide blade to aid in tracking.

I've looked that up Allen..and found this ....When you think about it the end blade most likely had no teeth and was just a guide blank ( set a little bit deeper to fit in the last sawed slot ...Maybe! Who knows ?I'm currently reading a marquetry book by Silas Kopf.

In it he talks of the French timbre merchants and specialised veneer resawers in the 1600's that cut all that exotic and very expensive tropical hardwood that was showing up from around the world by hand. They got to the point of being able to cut 2.3 - 2.5mm slices accurately using a method that is similar to the pit saw technique. Some of the line drawings of the time depict saws with multiple blades evenly spaced apart in order to cut more than one veneer at a time.

Resurrecting this thread rather than creating a new one.

I have a lump of walnut and some maple I want to resaw for soundboards and sides, but my bandsaw is too tiny. So I am considering building a frame saw and having at it (after practising on something cheap). I could use broken bandsaw blades, but the ones I have are also quite thin. Do you experts think a mitre saw blade might be usable in a frame saw? I see some fairly cheap on line and even at Wickes

http://www.wickes.co.uk/compound-mitre-saw-blade-60cm/invt/186774/

Cheers

Max