D

dhoenisch

Guest

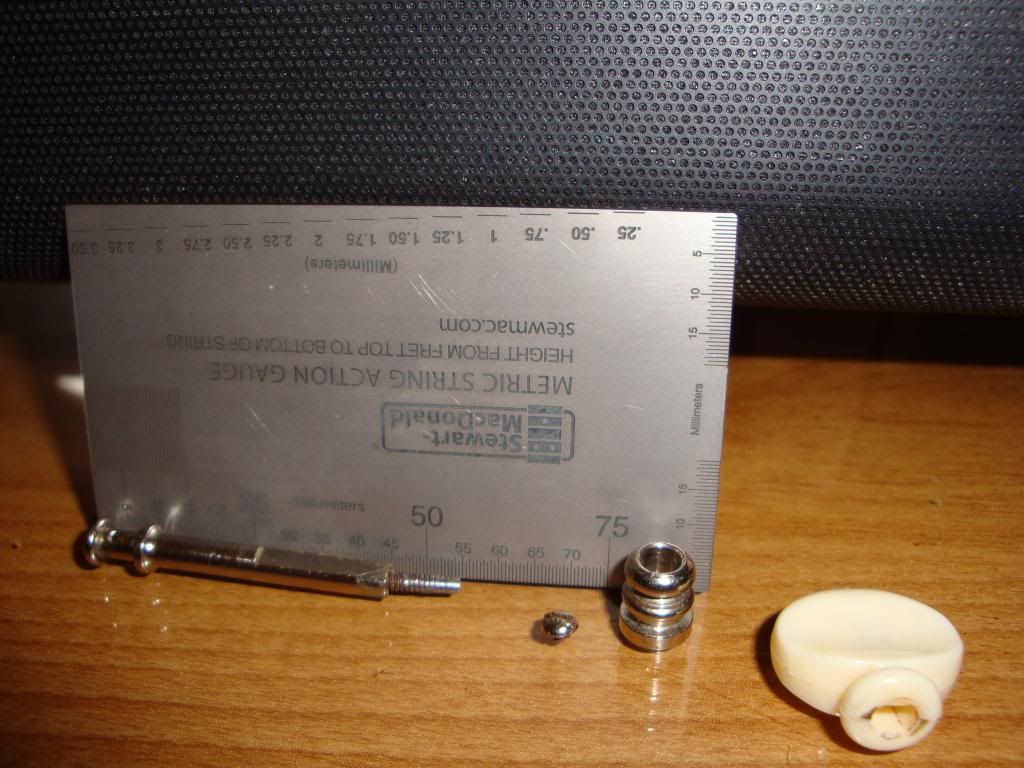

Does anyone have an old Harmony Baritone friction peg or pegs laying around? I was working on my mom's baritone, and the screw on one of them was rusted so well that it welded itself in the shaft, and nothing I do seems to be removing what is left in the shaft. I just need one peg, but will take what I can get as she want's the uke left original.

Thanks,

Dan

Thanks,

Dan

Attachments

Last edited: