Stompfrog

Active member

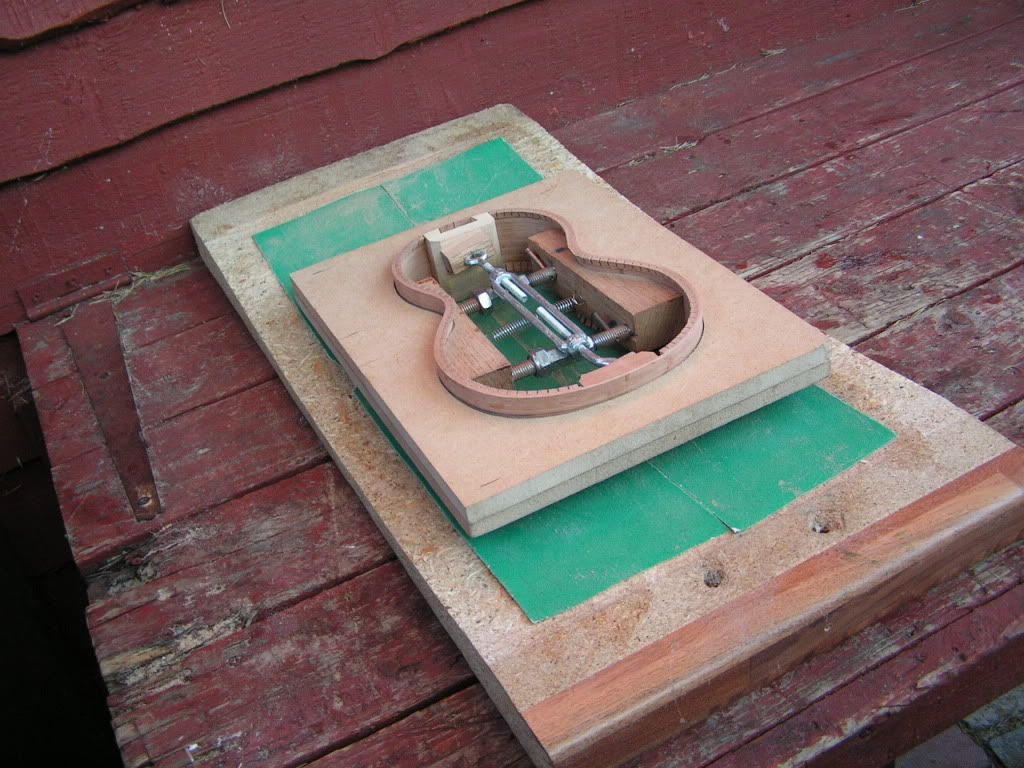

Today I began work on my first ever ukulele. Before I get anywhere near the tone woods I am planning on making a whole load of moulds, jigs, clamps etc as I intend to make more than one uke.

As well as staring work on the mould today I also began making a clamp (spreader?) to hug the inside of the uke waist and exert an outwards pressure onto the surrounding mould.

I wanted to pad the end of the curved wooden blocks making up the clamp to prevent any damage to the uke sides and to spread even pressure. I was considering getting some cork but had concerns about durability. in the end I bought some 3mm neoprene off eBay which I think will work really well.

My only concern... And question to the experienced folk of the forum is... Will the neoprene react with any tone woods unfavourably?

Many thanks in advance.

As well as staring work on the mould today I also began making a clamp (spreader?) to hug the inside of the uke waist and exert an outwards pressure onto the surrounding mould.

I wanted to pad the end of the curved wooden blocks making up the clamp to prevent any damage to the uke sides and to spread even pressure. I was considering getting some cork but had concerns about durability. in the end I bought some 3mm neoprene off eBay which I think will work really well.

My only concern... And question to the experienced folk of the forum is... Will the neoprene react with any tone woods unfavourably?

Many thanks in advance.