Paul Henneberry

Well-known member

Howdee,

I have recently completed my first three scratch built ukes (http://forum.ukuleleunderground.com/showthread.php?93820-The-heaviest-saprano-ever) and I thought I might share some information about the probably over the top jigs and tools that I made as the need arose during the project. In all cases I started by mining the wealth of knowledge that had already been freely shared through this forum but in most cases I came up with my own method of producing the jigs. The tools and materials that I had available usually played a big part in the method that I came up with.

I have already covered how I made radius dishes http://forum.ukuleleunderground.com/showthread.php?94298-a-new-way-of-making-a-radius-dish

So moving right along: fret slot cutting.

I’m very comfortable using power and battery tools and had already collected a few dewalt 18 volt battery tools and when I saw the 6” fret slot cutting blade in the stewmac catalogue I thought this might be an opportunity to add another yellow toy to my collection. I had checked out the preferred method of using this blade in a table saw on you tube but decided to try something different and anyhow, none of my table saws had a 5/8 arbour. I regularly use a bridge jig with a router sliding between guides and over the job in other woodcraft projects so I thought I’d use a similar method for a circular saw. In fact it is one of my router bridge jigs that has been repurposed to drill the holes in the template in the first photo but I have stopped the router sliding by blocking it in place. Until recently the dewalt DC390 was sold with a magnesium sole but this has been replaced with a cheaper pressed steel sole. I wanted the magnesium soled model because I reasoned I wanted it to slide between guides without any side to side wobble and that I could dress the sides of the cast magnesium sole to be exactly straight and parallel. A bit of shopping around and I found some old stock and the model I wanted. Out of the box the casting was fairly good but a few swipes over my router table against a straight fence made the sides perfectly straight and parallel. I probably voided the warranty but it was cheap and the dewalt stuff lasts forever anyhow. It was slightly bowed and not wanting to break it by bending it flat I ended up screwing a false base of 10mm phenolic sheet to it which pulled it flat. I suppose you could buy the steel soled saw and do this as well.

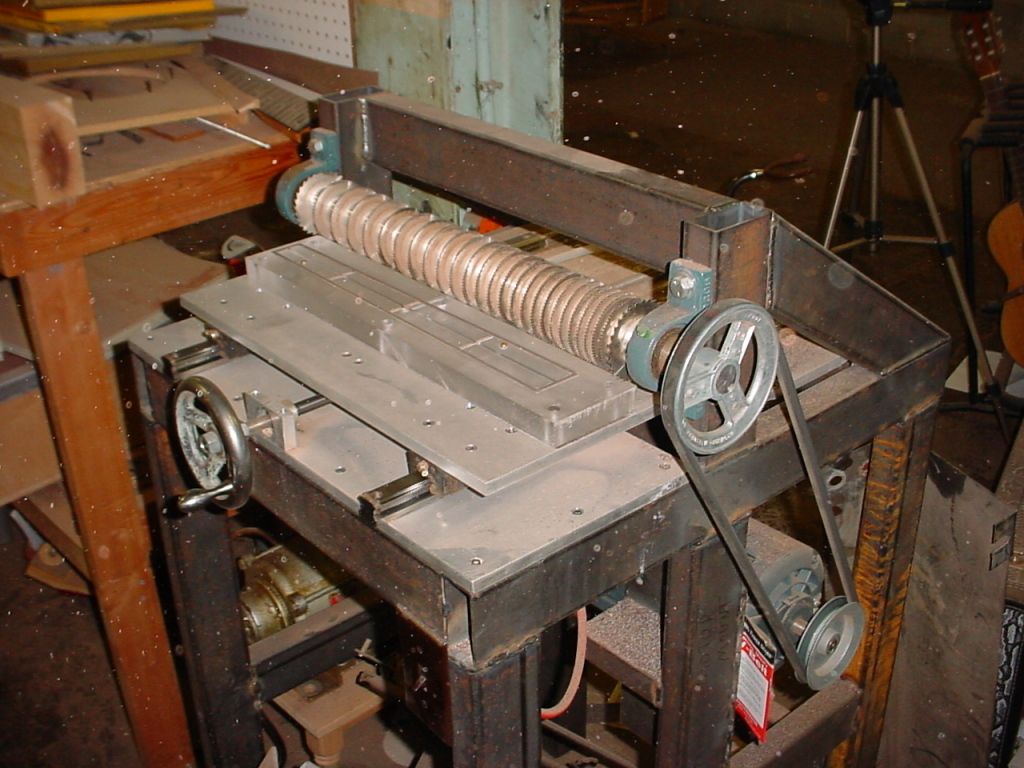

With this done I turned my attention to making an accurate fret spacing template out of 6mm phenolic sheet. I picked some features I liked from a few different sources and set about producing my own. Stewmac have a very useful fret space calculator available on their website and this is what I used. The most accurate tool I have for plunging an accurate hole is my dewalt plunge router. I already had an old 12” dial vernier caliper so I set up the system in the photo which I hope you can follow. Clamp, plunge, release, index forward using the fret spacing table and the caliper, clamp, plunge etc.

The mulga fret board blank was attached to the finished template with double sided tape. It slides under the bridge of the sawing jig and is positioned using the 8mm holes produced in the previous step and the screw tipped handle. The handle has an 8mm steel dowel and a 6mm thread on the end. The thread on the end of the handle screws into a threaded insert fitted in the saw jig. The handle locates and holds the fret template and fret board blank captive while the saw is slid over the top, cutting the slot. The slots were perfect without any tear out at all. Some way of fine adjusting the depth of cut would be an improvement but I did this by trial and error for now. A little bit of white spirits (naphtha, dry cleaning fluid) wicked between the fret board blank and the template dissolved the adhesive on the double sided tape and the fret board is released and ready for tapering.

I’m posting this information about the techniques that I came up not with to be critical of other methods to or say that this is better but only to get people to consider developing their own methods based on what they have available or feel comfortable with.

cheers

Paul

I have recently completed my first three scratch built ukes (http://forum.ukuleleunderground.com/showthread.php?93820-The-heaviest-saprano-ever) and I thought I might share some information about the probably over the top jigs and tools that I made as the need arose during the project. In all cases I started by mining the wealth of knowledge that had already been freely shared through this forum but in most cases I came up with my own method of producing the jigs. The tools and materials that I had available usually played a big part in the method that I came up with.

I have already covered how I made radius dishes http://forum.ukuleleunderground.com/showthread.php?94298-a-new-way-of-making-a-radius-dish

So moving right along: fret slot cutting.

I’m very comfortable using power and battery tools and had already collected a few dewalt 18 volt battery tools and when I saw the 6” fret slot cutting blade in the stewmac catalogue I thought this might be an opportunity to add another yellow toy to my collection. I had checked out the preferred method of using this blade in a table saw on you tube but decided to try something different and anyhow, none of my table saws had a 5/8 arbour. I regularly use a bridge jig with a router sliding between guides and over the job in other woodcraft projects so I thought I’d use a similar method for a circular saw. In fact it is one of my router bridge jigs that has been repurposed to drill the holes in the template in the first photo but I have stopped the router sliding by blocking it in place. Until recently the dewalt DC390 was sold with a magnesium sole but this has been replaced with a cheaper pressed steel sole. I wanted the magnesium soled model because I reasoned I wanted it to slide between guides without any side to side wobble and that I could dress the sides of the cast magnesium sole to be exactly straight and parallel. A bit of shopping around and I found some old stock and the model I wanted. Out of the box the casting was fairly good but a few swipes over my router table against a straight fence made the sides perfectly straight and parallel. I probably voided the warranty but it was cheap and the dewalt stuff lasts forever anyhow. It was slightly bowed and not wanting to break it by bending it flat I ended up screwing a false base of 10mm phenolic sheet to it which pulled it flat. I suppose you could buy the steel soled saw and do this as well.

With this done I turned my attention to making an accurate fret spacing template out of 6mm phenolic sheet. I picked some features I liked from a few different sources and set about producing my own. Stewmac have a very useful fret space calculator available on their website and this is what I used. The most accurate tool I have for plunging an accurate hole is my dewalt plunge router. I already had an old 12” dial vernier caliper so I set up the system in the photo which I hope you can follow. Clamp, plunge, release, index forward using the fret spacing table and the caliper, clamp, plunge etc.

The mulga fret board blank was attached to the finished template with double sided tape. It slides under the bridge of the sawing jig and is positioned using the 8mm holes produced in the previous step and the screw tipped handle. The handle has an 8mm steel dowel and a 6mm thread on the end. The thread on the end of the handle screws into a threaded insert fitted in the saw jig. The handle locates and holds the fret template and fret board blank captive while the saw is slid over the top, cutting the slot. The slots were perfect without any tear out at all. Some way of fine adjusting the depth of cut would be an improvement but I did this by trial and error for now. A little bit of white spirits (naphtha, dry cleaning fluid) wicked between the fret board blank and the template dissolved the adhesive on the double sided tape and the fret board is released and ready for tapering.

I’m posting this information about the techniques that I came up not with to be critical of other methods to or say that this is better but only to get people to consider developing their own methods based on what they have available or feel comfortable with.

cheers

Paul