RPA_Ukuleles

Well-known member

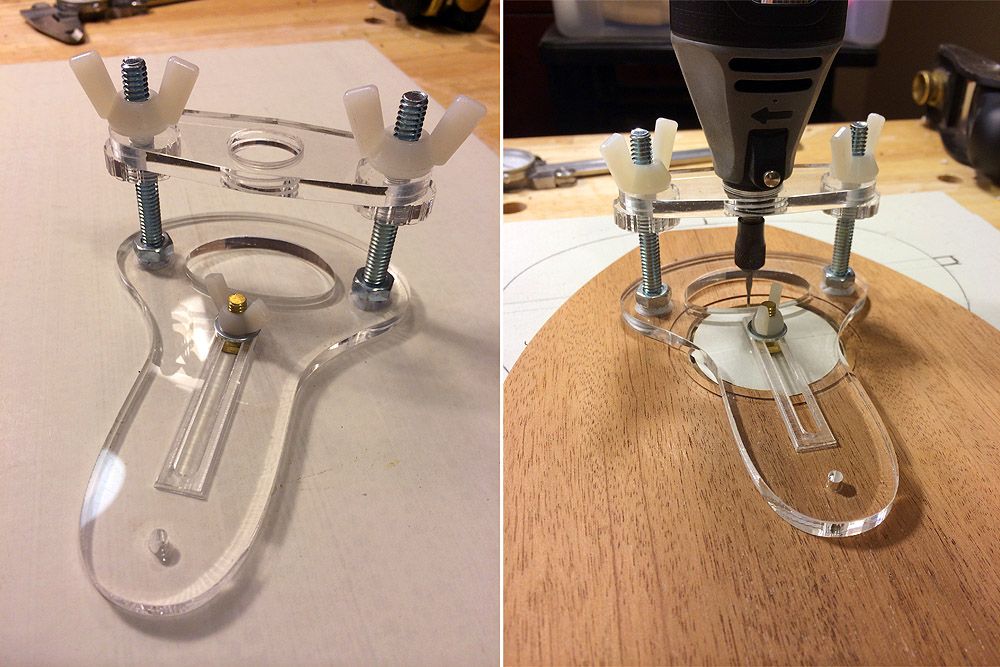

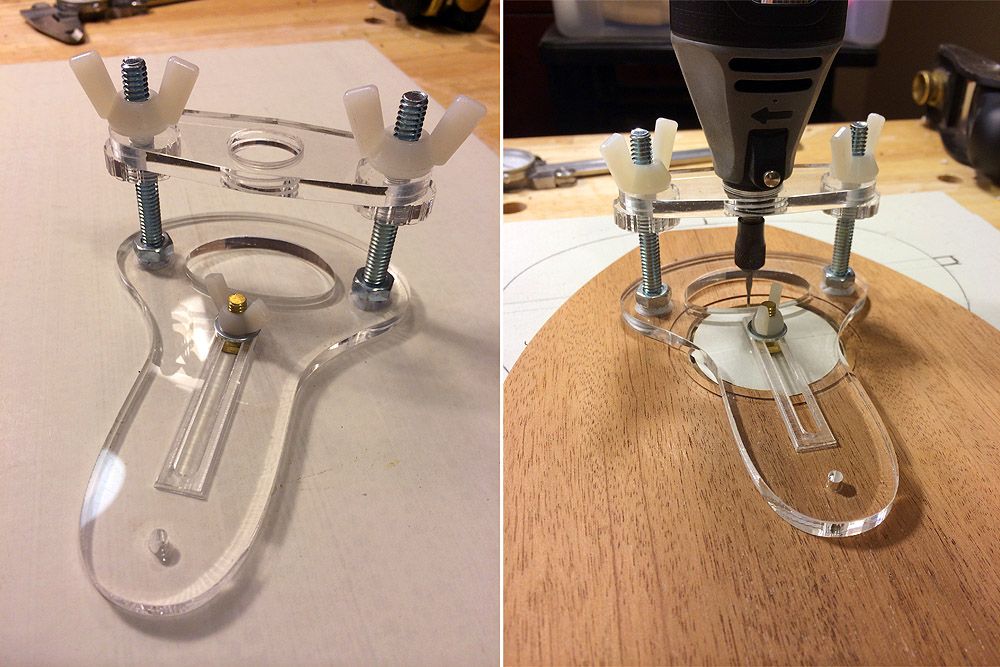

Made a new rosette/soundhole cutter to use with a Dremel. Drew it up in Adobe Illustrator and cut the parts from 1/4" acrylic on a laser. Had to etch away a recess in the back of the base to accept the retaining nut on the pivot pin. The nylon wingnuts tighten easily and don't vibrate loose. I threaded the tool plate with a 3/4"-12 tap and the Dremel screws right in. I wanted to make one of acrylic so I could see everything while working - but will likely have to polish out fine scratches regularly. Works great!