I've bent sides by using my wife's iron. Apply the iron over a very damp cloth and it will drive steam into the wood. You may have to re-wet the cloth a time or two. You then have to work quickly to get it into the mold and clamped down to shape. I've done it with maple, and with spruce - it may work with mahogany. It's worth a try.

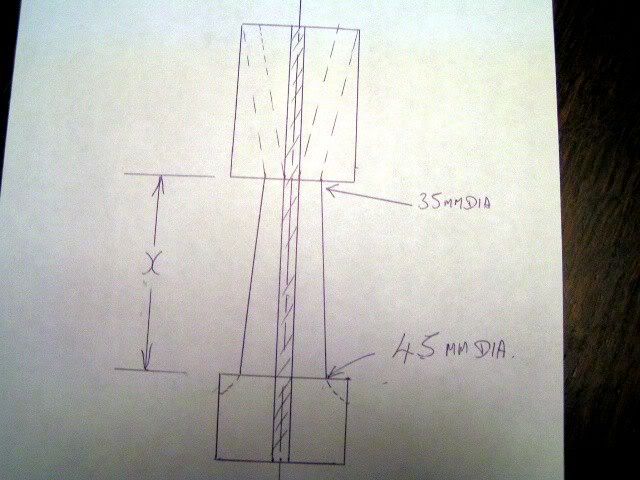

It is not difficult to make a tubular bending iron of the old traditional sort. The modern "blanket" benders are highly desirable, but you don't NEED one for hobby work.

Ukantor.

It is not difficult to make a tubular bending iron of the old traditional sort. The modern "blanket" benders are highly desirable, but you don't NEED one for hobby work.

Ukantor.