bacchettadavid

Well-known member

Part IV cont’d - Work-in-Progress; needs to be edited for needless words

E. CABLE MANAGEMENT

As the demands placed upon your board increase, good cable management becomes an increasingly wise investment of time and resources. This section will function as a walkthrough for wiring up the board in example D.7. The processes used in this example can be applied to most board layouts.

E.1 Preliminary Planning

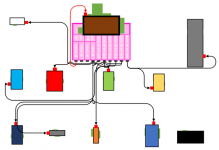

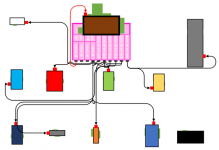

Before trying to figure out how to route each individual cable, I find it helpful to map out my signal chain and power supply connections as if laying out pedals on the floor. This helps me visualize my connections and keep track of where everything goes in later sections. It also helps me identify how many cables of each type I will require (though not their lengths)

For the sake of clarity, the power supply throughout these illustrations has been enlarged to show detail:

Fig. 1: Simplified signal chain diagram

Fig. 2: Simplified power connections diagram

These illustrations clarify that I will require 12 TS right angle to TS right angle patch cables (24 TS plugs + approx. 20’ of cable), 1 TRS right angle to TRS right angle patch cable (for the looper footswitch controller), 1 single-plug positive pin power cable (for the preamp/DI, which uses positive pin polarity) with a 2.1mm barrel connector, 4 single-plug negative pin power cables with 2.1mm barrel connectors, and 3 dual-plug negative pin power cables with 2.1mm barrel connectors.

Making cables is beyond the scope of this series, but if you are investing in a pedalboard, you may want to consider soldering your own cables. Making your own cables using quality components is pretty straightforward and usually costs 50% less than buying pre-made cables of reasonable quality.

E.2: Patch and Power Cable Layout

Once I have an idea of which plugs go where, I begin to lay out the actual connections themselves.

I begin by arranging the pedals according to my intended layout, providing additional negative space to preserve visual clarity of the cable runs. Note that I have flipped the power supply over to reflect the fact that it would be mounted upside-down below the pedalboard mounting surface.

Fig. 3: Expanded pedalboard layout

I then sort out my patch cable runs. I plan for patch cables first because they are much more expensive than power cables, and unnecessary patch cable length can lead to signal degradation.

Fig. 4: Map of patch cable runs

As you can see, I have consolidated patch cable routing where possible. This does sometimes add a bit of cable length but simplifies cable management and troubleshooting of any connection issues. As an added plus, it also makes it easier to minimize route sharing with power cables.

Note that I try to avoid the creation of any patch cable coils. Coils can, in some circumstances, result in audible AC induction from nearby appliances and wiring within venues. The TRS cable to the footswitch controller and the TS cable to the tuner could probably be coiled if necessary.

Once the patch cables are done, I map out the power cables using the same layout. Once again, I try to consolidate cable runs wherever possible:

Fig. 5: Map of power cable runs

I then combine the layouts and negotiate the cable runs to minimize interference between power cables and patch cables. This decreases risk of noise and simplifies the troubleshooting process when issues arise. As wish patch cables, you should endeavor to avoid the formation of any coils.

Fig. 6: Expanded version of master wiring diagram

E.3: Testing and Finalization

At this stage, I strongly recommend wiring everything up (power cables first, then patch cables) on the pedalboard and testing each unit while the signal chain is plugged in. You can do this either on or off the board (I prefer on, but it’s generally easier to use something akin to the floor layout above). This testing should include at least the following steps:

Once you’ve isolated and addressed any problems, you are ready to wire up your board one last time and affix the cables via your preferred method of cable management (snakeskin, Velcro, reusable zip ties, etc.)

E. CABLE MANAGEMENT

As the demands placed upon your board increase, good cable management becomes an increasingly wise investment of time and resources. This section will function as a walkthrough for wiring up the board in example D.7. The processes used in this example can be applied to most board layouts.

E.1 Preliminary Planning

Before trying to figure out how to route each individual cable, I find it helpful to map out my signal chain and power supply connections as if laying out pedals on the floor. This helps me visualize my connections and keep track of where everything goes in later sections. It also helps me identify how many cables of each type I will require (though not their lengths)

For the sake of clarity, the power supply throughout these illustrations has been enlarged to show detail:

Fig. 1: Simplified signal chain diagram

Fig. 2: Simplified power connections diagram

These illustrations clarify that I will require 12 TS right angle to TS right angle patch cables (24 TS plugs + approx. 20’ of cable), 1 TRS right angle to TRS right angle patch cable (for the looper footswitch controller), 1 single-plug positive pin power cable (for the preamp/DI, which uses positive pin polarity) with a 2.1mm barrel connector, 4 single-plug negative pin power cables with 2.1mm barrel connectors, and 3 dual-plug negative pin power cables with 2.1mm barrel connectors.

Making cables is beyond the scope of this series, but if you are investing in a pedalboard, you may want to consider soldering your own cables. Making your own cables using quality components is pretty straightforward and usually costs 50% less than buying pre-made cables of reasonable quality.

E.2: Patch and Power Cable Layout

Once I have an idea of which plugs go where, I begin to lay out the actual connections themselves.

I begin by arranging the pedals according to my intended layout, providing additional negative space to preserve visual clarity of the cable runs. Note that I have flipped the power supply over to reflect the fact that it would be mounted upside-down below the pedalboard mounting surface.

Fig. 3: Expanded pedalboard layout

I then sort out my patch cable runs. I plan for patch cables first because they are much more expensive than power cables, and unnecessary patch cable length can lead to signal degradation.

Fig. 4: Map of patch cable runs

As you can see, I have consolidated patch cable routing where possible. This does sometimes add a bit of cable length but simplifies cable management and troubleshooting of any connection issues. As an added plus, it also makes it easier to minimize route sharing with power cables.

Note that I try to avoid the creation of any patch cable coils. Coils can, in some circumstances, result in audible AC induction from nearby appliances and wiring within venues. The TRS cable to the footswitch controller and the TS cable to the tuner could probably be coiled if necessary.

Once the patch cables are done, I map out the power cables using the same layout. Once again, I try to consolidate cable runs wherever possible:

Fig. 5: Map of power cable runs

I then combine the layouts and negotiate the cable runs to minimize interference between power cables and patch cables. This decreases risk of noise and simplifies the troubleshooting process when issues arise. As wish patch cables, you should endeavor to avoid the formation of any coils.

Fig. 6: Expanded version of master wiring diagram

E.3: Testing and Finalization

At this stage, I strongly recommend wiring everything up (power cables first, then patch cables) on the pedalboard and testing each unit while the signal chain is plugged in. You can do this either on or off the board (I prefer on, but it’s generally easier to use something akin to the floor layout above). This testing should include at least the following steps:

- Cycle power to each unit several times to ensure that the unit reliably powers on.

- Turn all units on at once for several minutes; check power supply temperature. periodically to make sure you are not overloading any of the outputs.

- Send from board to your amplifier or mixer. Send from instrument to pedalboard. Turn on all units for each isolated outlet, one outlet at a time. Listen for excessive noise.

- At stage volume, run through all common combinations of effects to check noise levels.

Once you’ve isolated and addressed any problems, you are ready to wire up your board one last time and affix the cables via your preferred method of cable management (snakeskin, Velcro, reusable zip ties, etc.)

Attachments

Last edited: