thistle3585

Well-known member

maybe mandolins can be ok with it what size are the nuts?

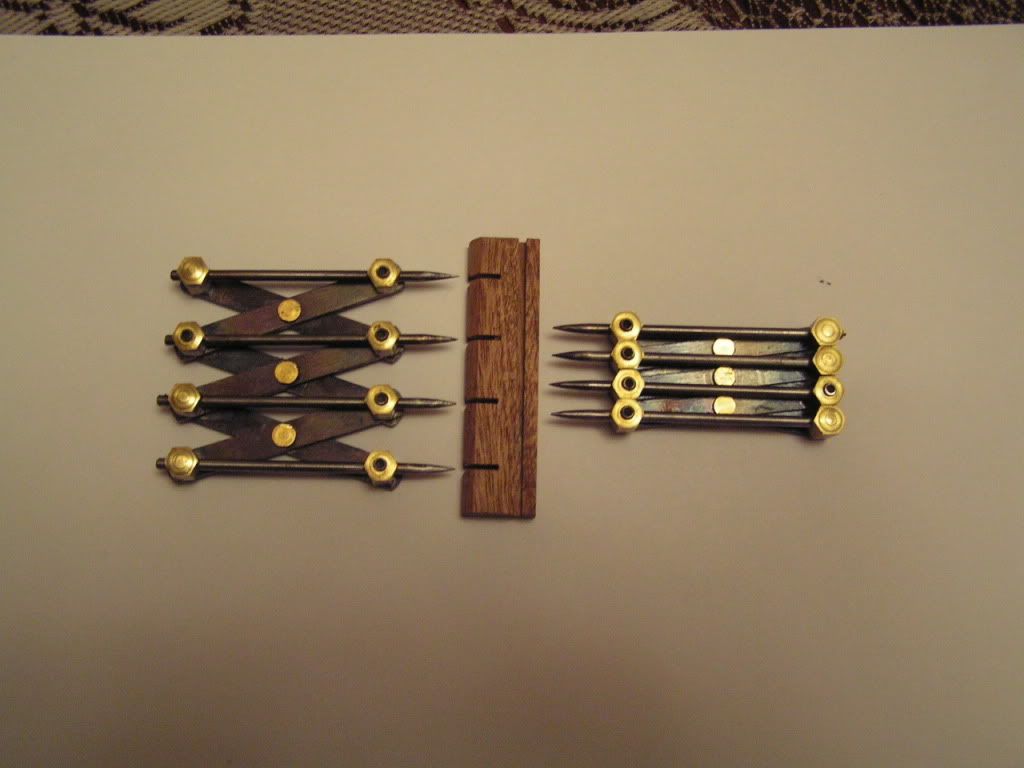

Smallest is 1" but 1.0625" to 1.125" seems to be the norm. I'm happy with the SM ruler to draw out my nuts on my single course strings but I could see a lot of value in your tool for laying out paired courses on mandolins.