Timbuck

Well-known member

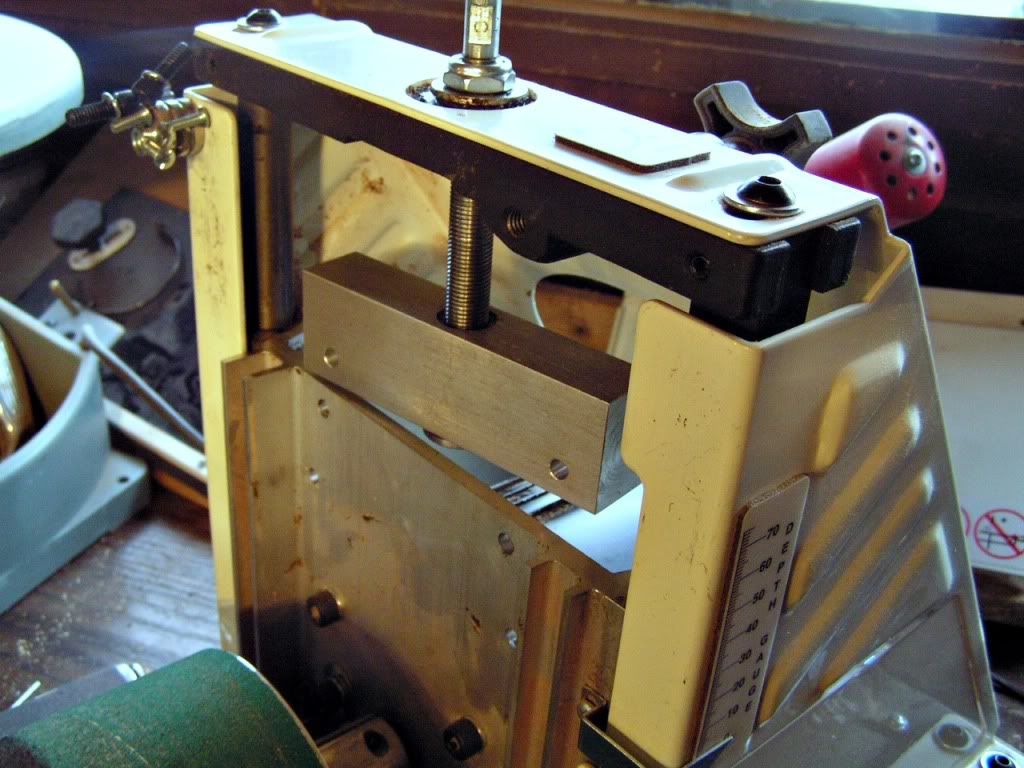

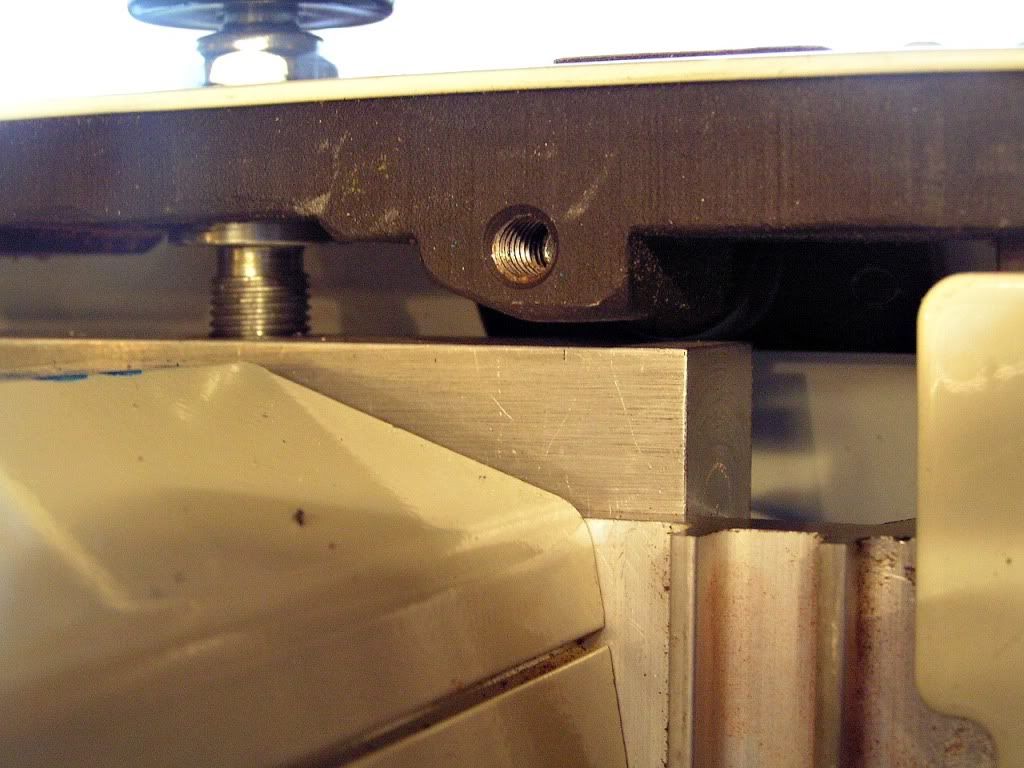

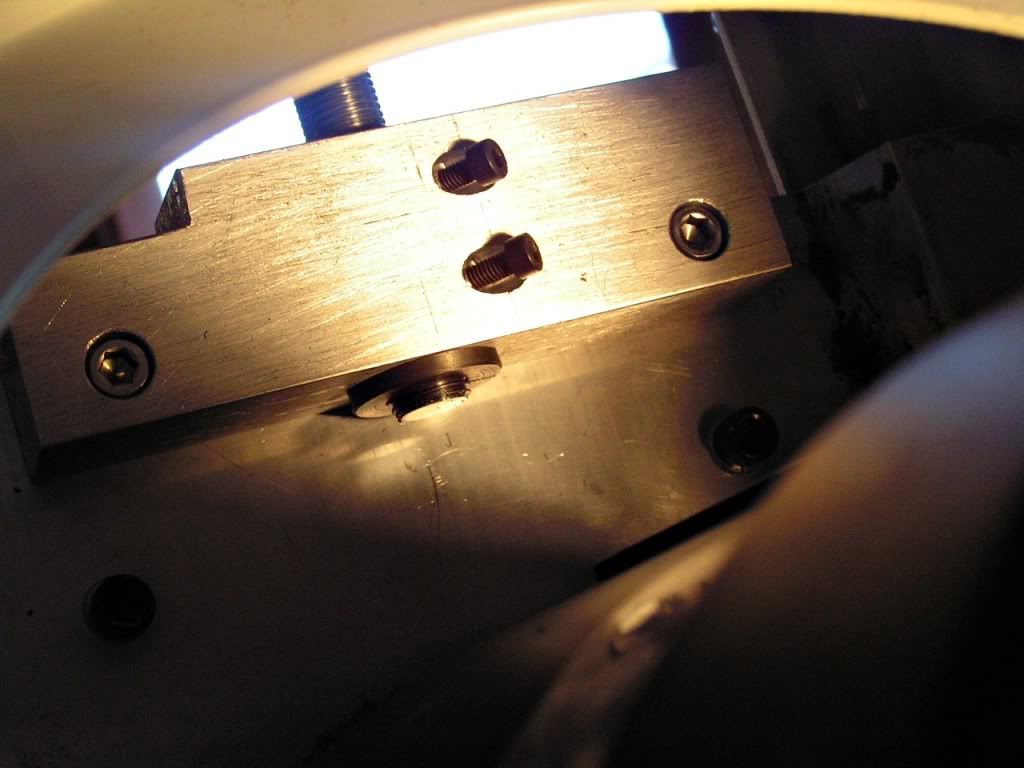

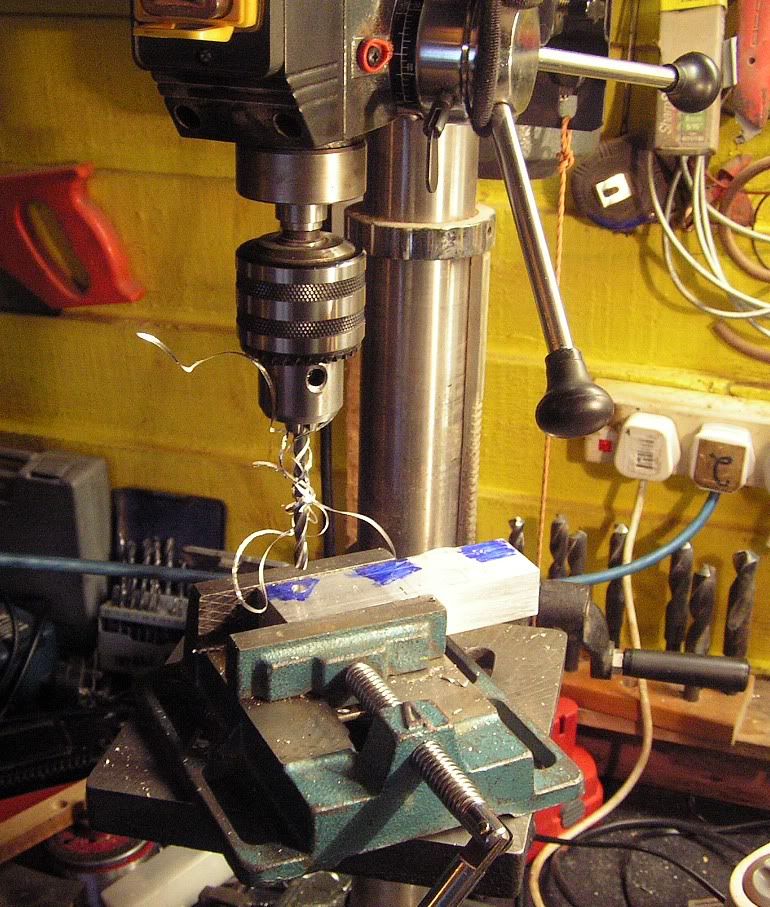

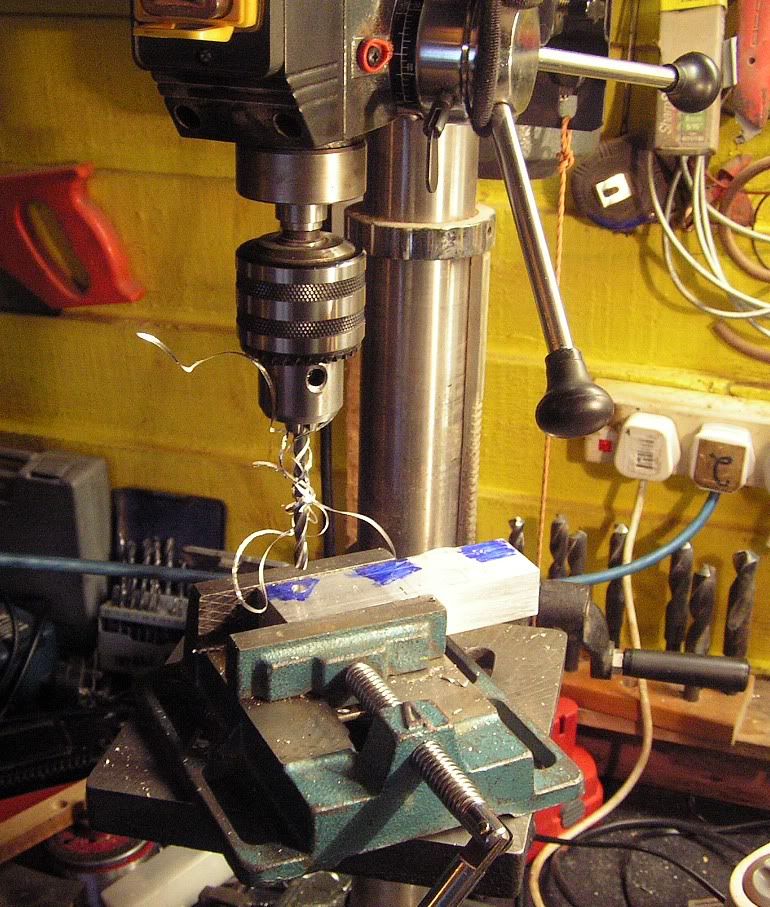

Next over to the Pedestal drill to complete machining on this part.

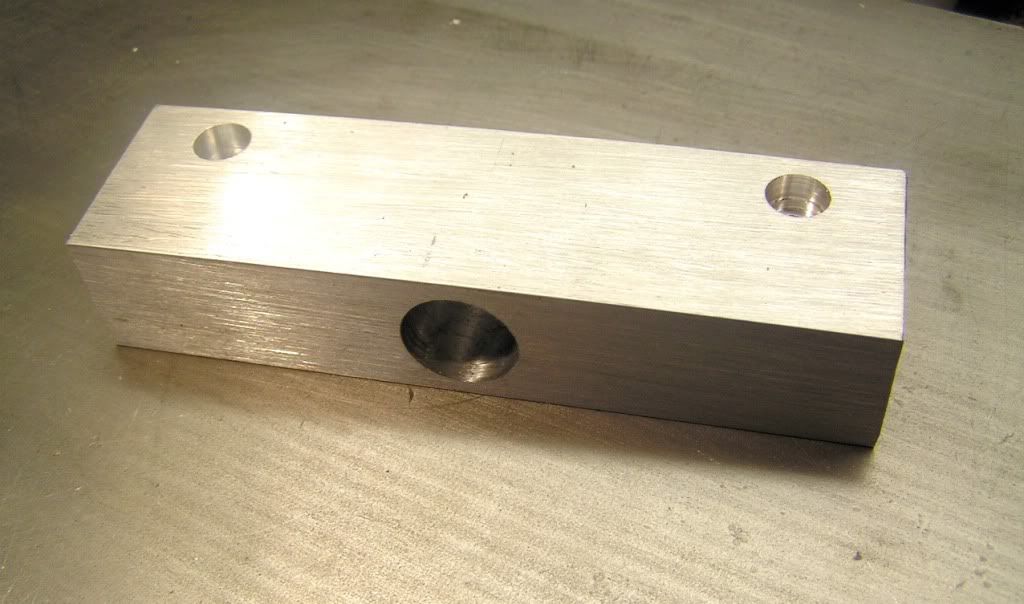

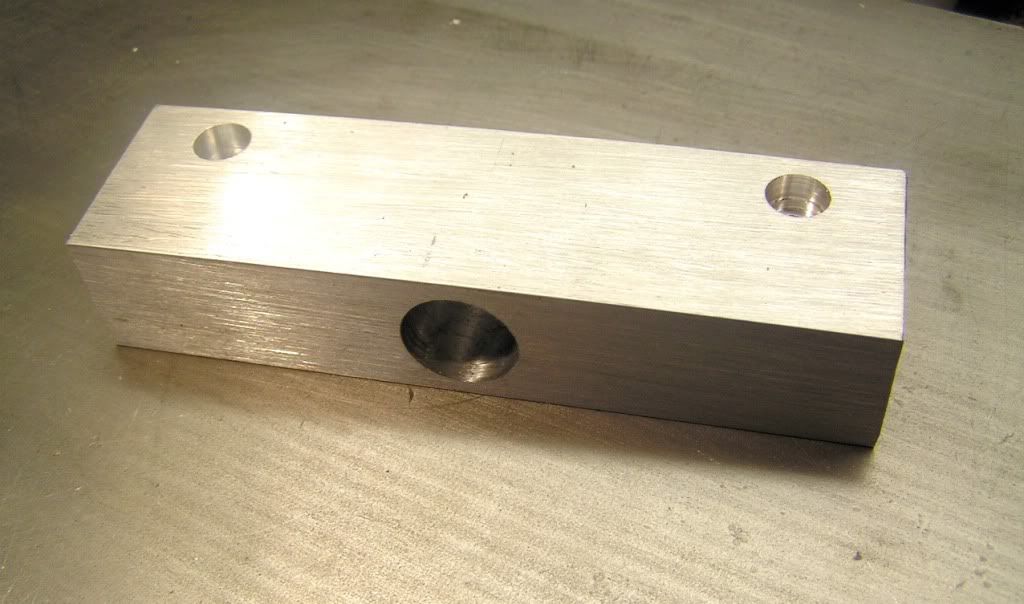

And after a little fettling here's the completed part.

And after a little fettling here's the completed part.